china aluminium low pressure die casting factory

china aluminium low pressure die casting factory focuses on innovation in low pressure die casting, offering fully customized aluminum and zinc components with precise tolerances, superior mechanical strength, and refined surface finishes. We provide end-to-end solutions for automotive, electronics, industrial, and aerospace applications.

Comprehensive Custom Services

By utilizing advanced CAD/CAM and flow simulation, china aluminium low pressure die casting factory optimizes mold design, casting parameters, and finishing processes for each project. Clients can specify alloys, dimensions, tolerances, and surface treatments tailored to their exact requirements.

Global Delivery and Professional Support

As a trusted manufacturer and supplier, china aluminium low pressure die casting factory ensures consistent quality, international logistics, and responsive technical guidance for every custom order, supporting clients worldwide with high-performance, fully customized castings.

Gas Meter Valve Housing Casting

Customers come to the customized gas meter accessories aluminum castings, presumably a specific gas meter valve body housing. The gas meter valve housing not only protects the internal components, but also assumes multiple functions such as connecting the inlet and outlet ports and supporting the mechanical seals.

Gas Meter Valve Housing Casting

Customers come to the customized gas meter accessories aluminum castings, presumably a specific gas meter valve body housing. The gas meter valve housing not only protects the internal components, but also assumes multiple functions such as connecting the inlet and outlet ports and supporting the mechanical seals.

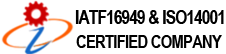

Dental Chair Part Casting

This is a customized aluminum casting, which is an important part of a dental chair. This dental chair aluminum casting adopts aluminum high-pressure die-casting one-piece molding plus cnc machining process, the finished product not only has excellent mechanical properties and good processing accuracy, but also has good lightweight, corrosion resistance, compact design and easy to install and maintain.

Dental Chair Part Casting

This is a customized aluminum casting, which is an important part of a dental chair. This dental chair aluminum casting adopts aluminum high-pressure die-casting one-piece molding plus cnc machining process, the finished product not only has excellent mechanical properties and good processing accuracy, but also has good lightweight, corrosion resistance, compact design and easy to install and maintain.

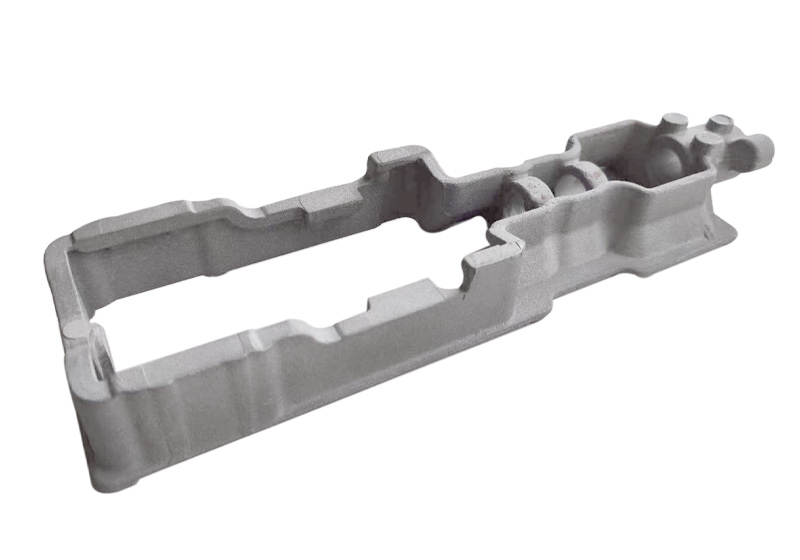

Metering Device Frame Casting

This is an aluminum casting for precision measuring instruments. Frame metering device casting not only protects the internal core components, but also performs multiple functions such as positioning and guiding, sealing, thermal management, and mechanical support.

Metering Device Frame Casting

This is an aluminum casting for precision measuring instruments. Frame metering device casting not only protects the internal core components, but also performs multiple functions such as positioning and guiding, sealing, thermal management, and mechanical support.