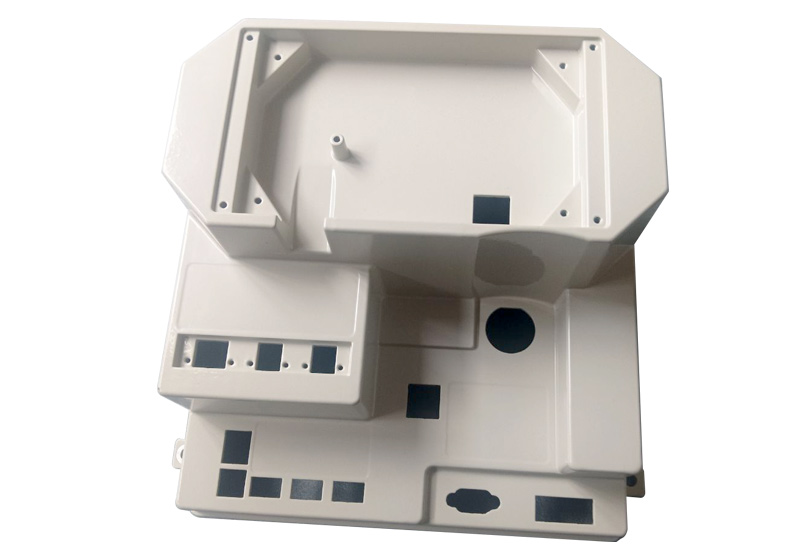

Power Module Enclosure Castings

This is a customized enclosure for a power integration module, serving as a casting shell in the power system to carry and protect the core electrical components inside the control unit.

Aluminum power castings are critical to modern electrical and energy applications, offering the strength, precision, and thermal performance required for power modules, inverters, and electronic housings. With advanced aluminum die-casting processes, such as high-pressure and vacuum die casting, complex components can be produced with excellent dimensional accuracy, reliable sealing, and superior mechanical strength.

In today’s power electronics systems—including renewable energy inverters, electric vehicles, and industrial power modules—aluminum castings play a key role in heat-sensitive applications, such as power module enclosure castings and electronic module housings. Their lightweight design, corrosion resistance, and high thermal conductivity make them ideal for ensuring durability and efficient heat dissipation.

Backed by optimized mold design, simulation-driven engineering, and rigorous quality control, modern aluminum power castings deliver consistent performance and stable mass production, helping manufacturers achieve reliable, efficient, and long-lasting power electronic solutions.

As a key part of China’s power electronics and energy systems supply chain, aluminum power castings support the industry’s push toward reliability, efficiency, and thermal performance. With growing demand from EV, renewable energy, and industrial electronics manufacturers, advanced die-casting technologies are increasingly applied to enhance component precision, strength, and heat management.

Aluminum die-cast components—especially those used in power module enclosures and electronic housings—are essential for ensuring thermal stability, mechanical durability, and reliable performance across modern power systems.

Need custom power castings for electronic modules?

As a professional China-based power casting manufacturer, Innovaw offers custom aluminum castings and precision die-casting services for global OEMs and system integrators. With strong engineering capabilities and strict quality control, we deliver high-strength, lightweight, and cost-effective components for power modules, inverters, and electronic housings.

From custom power module enclosures to electronic housing castings, our team supports your project from design through mass production.

Request a free quote today and partner with a reliable China die-casting manufacturer for power applications.

This is a customized enclosure for a power integration module, serving as a casting shell in the power system to carry and protect the core electrical components inside the control unit.

This is a custom power electronics module housing designed primarily for structural support, thermal management, electromagnetic shielding, and protection. It encapsulates and safeguards the components and circuits within power integrated modules.

As a professional China-based manufacturer, Innovaw provides a full range of casting and machining services to support custom power module enclosures and electronic housing castings—from rapid prototyping to mass-production aluminum die casting. Our integrated capabilities ensure high efficiency, reliable quality, and strong technical support throughout every stage of your project.

Power module and electronic housing castings often face challenges such as porosity, shrinkage, inconsistent mechanical strength, and surface defects. These issues can compromise heat dissipation, electrical insulation, and long-term reliability.

Our advanced aluminum die casting technologies, combined with optimized process control and precise tooling, reduce internal defects and improve overall material density. Whether for high-performance electronic housings or power module enclosures, our solutions ensure stability, repeatability, and compliance with strict power electronics standards.

IATF 16949 / ISO 9001 Certified Manufacturing

Innovaw’s quality management system ensures consistent, high-strength, and reliable power aluminum castings. Advanced process monitoring and inspection detect defects in real time, supporting stable, repeatable production for critical electronic modules.

In-House Quality Inspection Lab

Our lab ensures stable quality through CMM and VMS measurement systems, spectrometer material testing, tensile and hardness verification, X-ray NDT for internal defects, and thermal performance testing for power electronics enclosures.

Innovaw specializes in precision aluminum die casting for power module enclosures, electronic housings, and thermal management components. Our solutions support high heat dissipation, electrical insulation, and structural reliability for power electronics applications.

Key applications include EV power module housings, inverter enclosures, electronic control units, and industrial power module casings. These components ensure efficient thermal performance, safe operation, and long service life under high electrical and thermal loads.

With advanced die casting, CNC machining, and customized engineering support, we manufacture high-quality aluminum power castings that meet strict industry standards for precision, strength, and durability.

With decades of experience in custom power aluminum casting, Innovaw delivers high-precision components designed for thermal management, electrical performance, and long-term reliability. Our engineering team supports your project from concept to mass production, ensuring optimized designs and cost-effective manufacturing.

By integrating rapid prototyping, tooling, die casting, CNC machining, and finishing under one roof, we help simplify your supply chain while improving quality and lead time for power electronics manufacturers.

As an ISO 14001, ISO 45001, SA8000, and ISO/IEC 27001 certified manufacturer, we maintain strict standards for quality, safety, sustainability, and data security. Our engineering tools—such as CAD/CAM, mold-flow simulation, and digital measurement systems—ensure precise, consistent, and reliable power casting production.

Innovaw offers a wide selection of aluminum alloys engineered for high thermal conductivity, corrosion resistance, and mechanical strength. We commonly use die-casting alloys suitable for electronic housings and power module enclosures, ensuring excellent fluidity, heat dissipation, and structural stability.

Comprehensive finishing options—including CNC machining, anodizing, powder coating, and protective coatings—are available to meet both functional and aesthetic requirements for power electronics applications.

In addition to aluminum die casting, Innovaw provides CNC machining, investment casting, sand casting, and rapid prototyping to support custom power module and electronic housing production.

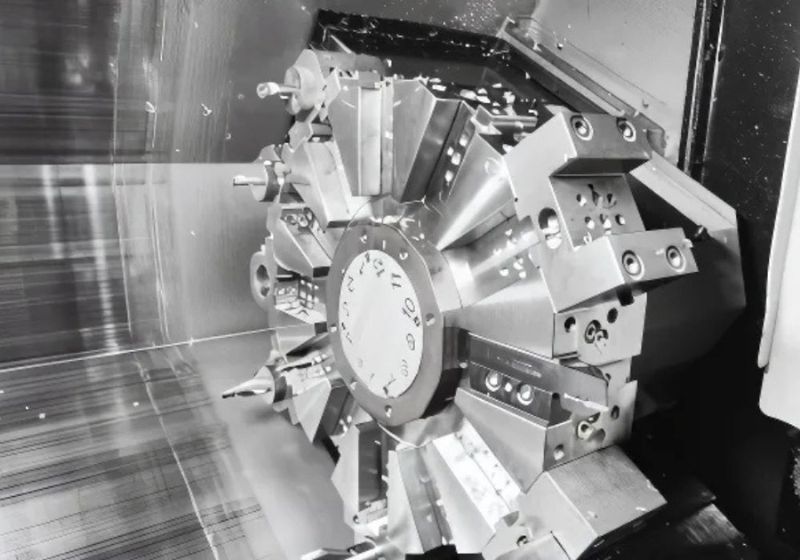

CNC Machining for Power Components

We provide high-precision CNC machining for complex power module housings, heat-dissipation structures, brackets, and functional prototypes, ensuring tight tolerances, consistent quality, and reliable delivery for both prototypes and mass-production runs.

Investment Casting for Power Components

For components requiring intricate geometries or low-volume flexibility, we offer aluminum investment casting solutions. This process delivers excellent dimensional stability and smooth surfaces, ideal for power module housings and electronic casings.

Sand Casting for Power Components

Sand casting is suitable for larger or thicker-wall components, such as industrial power housings and enclosures. Innovaw provides complete support from tooling to machining and finishing.

Gravity Casting for Power Components

Gravity casting is ideal for medium-volume power module enclosures that require higher mechanical strength and heat-treatment compatibility than high-pressure die casting. We offer mold design, casting, machining, and finishing for complete gravity-cast production.

Innovaw’s power aluminum castings and CNC-machined components are exported to global markets, including the United States, Germany, the United Kingdom, France, Australia, and more. We are ISO9001:2015 certified and comply with international quality standards to ensure every part meets the demanding requirements of power electronics and energy systems applications.

As a professional China manufacturer specializing in power aluminum die casting, we provide high-strength, thermally efficient, and cost-effective castings customized to your specifications. Send your inquiry or upload your drawings to receive a fast and accurate quotation.

Contact us to learn how our engineering team, advanced equipment, and precision tooling can deliver the best quality and value for your power aluminum casting project.

Empowering you to fully understand everything about us-start exploring now