Bicycle Aluminum Parts Development Case

Project Brief

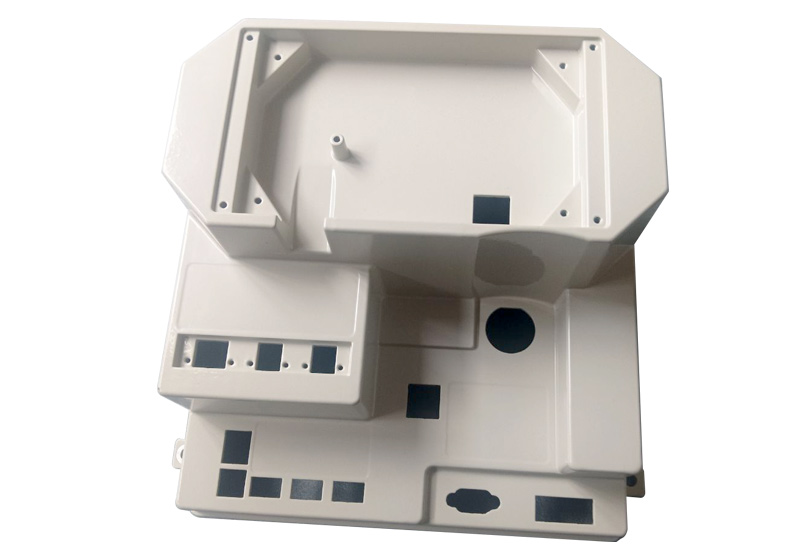

This is a custom-designed aluminum die-casting housing for a bicycle component, serving as the outer shell of an important part and requiring precise assembly.

1. Product Standards & Requirements: Material: K-ALLoy; General dimensional tolerance grade: ISO 8062-CT3; Flawless appearance (no visible defects); Surface roughness: Ra6.3µm; Exterior: black fine texture powder coating, thickness 100±20µm; Neutral salt spray test: 240 hours. PPAP approval must be completed and passed before formal mass production.

2. Product Challenges: The product has an unconventional, unique structure, posing difficulties in mold design. High appearance requirements involve both A-side and B-side surfaces.

Risk Keywords: Complex structure, High precision, Fracture, Assembly accuracy, Zero appearance defects

The overall project presented a significant challenge, particularly testing our capabilities in mold design and quality control.

Development Process

For this project, we formed a development team including mold designers, casting engineers, machining engineers, measurement engineers, quality engineers, and sales. The team applied the core methodology of the internationally advanced IATF 16949 standard - Advanced Product Quality Planning (APQP), entering a comprehensive product development process focused on quality.

We first conducted a DFM analysis of the product design. After communicating with the customer, we optimized certain structural details to enhance manufacturability while ensuring functionality, establishing mutually agreed-upon technical specifications and quality standards.

Considering the application environment and performance requirements of this bicycle component housing, the material was confirmed as K-ALLoy. Based on the material properties and the core design elements of the product, the process route of high-pressure die casting (HPDC) + CNC precision machining was ultimately determined, balancing technical feasibility, quality stability, and cost control.

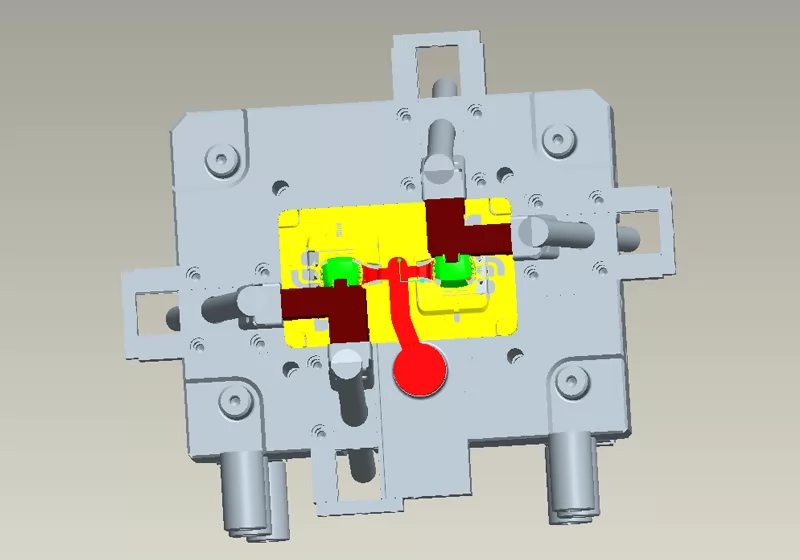

Subsequently, technical engineers performed mold simulation and mold flow analysis to predict and optimize various challenges and process parameters, and established preliminary Process Flow Charts and Control Plans.

Finally, the plan was gradually validated, and issues were identified and resolved in the subsequent practical stages.

Practice Validation & Optimization

Starting from mold manufacturing, the project entered the actual production phase. Our company proceeded according to the initial Process Flow Chart, established the Control Plan, and applied FMEA tools for risk analysis and assessment of various potential failure modes. The main key issues encountered during the actual manufacturing process were as follows:

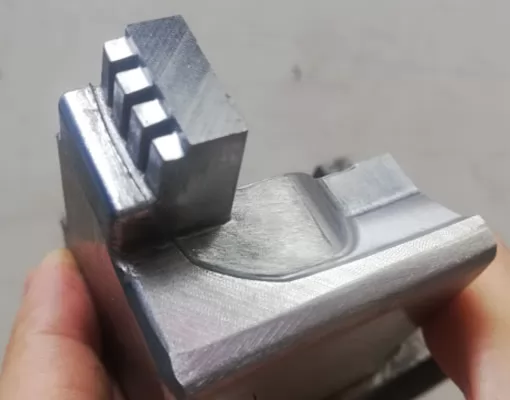

A. Mold Design Optimization Solves Side Hole Appearance Issue

During the sampling stage, quality inspection engineers discovered abnormal square hole shapes and thick flash on the edges during a comprehensive appearance check of the castings, which would affect customer assembly. The technical team immediately conducted a quality review and determined the root cause: Due to product structure constraints, ejector pins were located on the inner bottom surface of the product. During mold opening, the product could easily be punctured by the ejectors. If the top surface was punctured, the product could shift but not fully eject, causing the sliding core to collide with the stuck product during movement, resulting in damage to the sliding core end face.

Solutions:

1. Added backup side sliding cores.

2. Increased spray head water spraying time to reduce the risk of sticking.

3. Added sensors to the die-casting machine to promptly detect sticking and prevent sliding core impact damage.

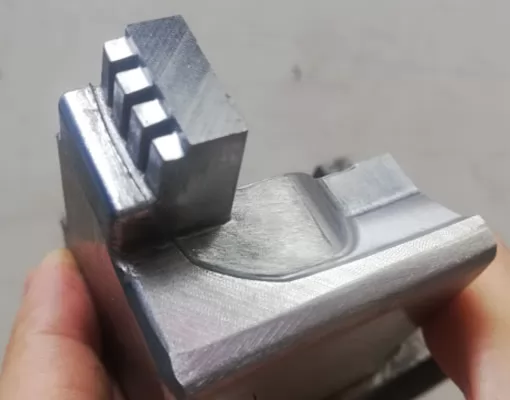

Problem Slider

New Slider

After implementing these solutions, multiple batch verifications showed very significant results, reducing the product defect rate from 60% to less than 2%.

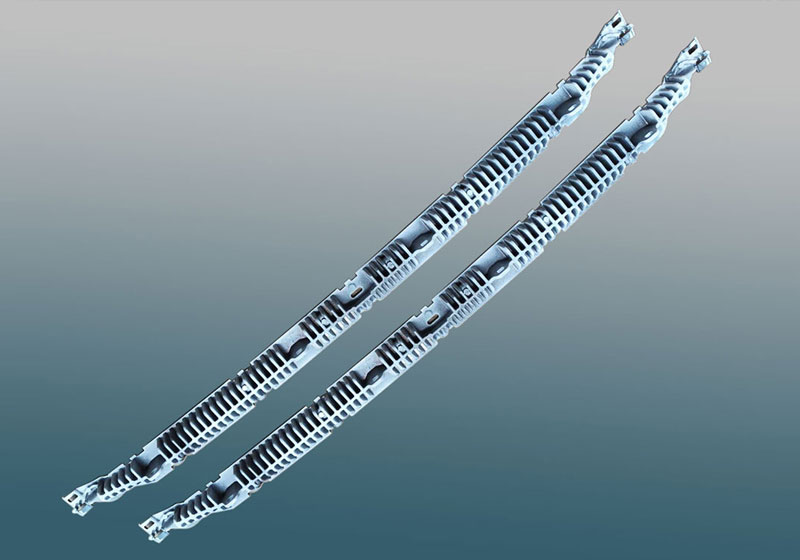

B. Operational Standards Solve Appearance Challenges

Product Appearance Requirements: The product surface must be free from defects such as cold shuts, short shots, porosity, flash, cracks, scratches, deformation, ejector pin marks, burrs, bumps, and scratches; critical assembly surfaces must be free from excess material or powder coating buildup; all appearance surfaces must have smooth transitions without uneven steps or polishing deformation defects; surface color should be uniform and consistent, without yellowing, spots, oil residue, exposed substrate, off-colors, pinholes, particles, buildup, or scratches.

This bicycle component had high appearance requirements, especially for the exterior surfaces after assembly, particularly the A-side and B-side. However, the 2D drawings were relatively simple and did not fully reflect detailed requirements, such as specific localized irregular angles. When the first batch of samples was submitted, the customer expressed dissatisfaction with the appearance details. The team actively addressed this. First, we engaged in deep communication with the customer, established detailed process documentation, created standard files for every detail requirement, and clarified operating requirements and specifications. Secondly, we strengthened training for operators to ensure every step was performed standardly and without deformation.

Different appearance surfaces of the product

Quality Control

The entire development process was a systematic procedure of identifying and controlling quality risks while continuously optimizing the process. The bicycle component housing project team leveraged rich experience and solid technology to conduct technical reviews and repeated verification at every process step, systematically identifying and tackling potential risk points. The team's quality engineers strictly adhered to the IATF 16949 quality system, implementing the full APQP process requirements to achieve full-process quality control. Throughout the process, various standardized documents and practices such as FMEA, SPC, MSA, and Control Plans were established and executed to prevent potential process risks, quality risks, and control quality variation. Finally, PPAP documentation was established and approved by the customer, laying a solid foundation for formal mass production.

The process included first-article inspection, in-process inspection, and outgoing inspection, establishing complete inspection data retention to ensure all quality data is traceable and verifiable.

Results and Evaluation

Finished Product Metrics:

1. Dimensional Accuracy: All met according to ISO 8062-CT3 requirements.

2. Surface Quality: Free from any visible defects; standard met.

3. Salt Spray Test: 240 hours completed.

5. PPAP completed and approved by the customer.

The development of this aluminum die-cast bicycle component project by Innovaw, characterized by its relatively high technical difficulty and stringent comprehensive performance requirements, served as a test of the manufacturer's overall capabilities. Relying on our profound expertise in high-pressure die casting, precision CNC machining capabilities, and an excellent quality management system consistently implemented throughout the process, we successfully overcame the challenges and delivered a high-quality product that met and even exceeded customer expectations. This fully demonstrates our casting development team's professional capability for systematic problem analysis and rapid closed-loop improvement in developing complex structural components.

Production Process

Mould making→Melting→High Pressure Die Casting→Cutting the sprue and riser→Polishing→Deburring→Shot Blasting→Machining→Powder Coating→Packaging & inspection

FAQs

Q1. How to get a quote?

We ask for 3D models or detailed 2D drawings. Samples may also be provided for pricing purposes. Please also provide specific details such as the product quantity, annual demand, raw materials, and dimensional tolerances. We accept 3D models in .PRT and .SLDPRT formats, as well as neutral formats such as .IGS, .STP, and .X_T.

Q2. What is the minimum order quantity for the product?

Q3. How long does it usually take to deliver the product?

Because the customer's product demand and complexity is different, need to use different die-casting or casting process, so the delivery time is not the same, we will be with the customer before booking the contract for delivery time confirmation. tooling lead time: 5-8weeks according to different parts; first samples lead time: 1-3weeks after tooling ready. mass order lead time: 5-7weeks

Q4. How to ensure quality?

we will use 8D tool to process customer's complaint, define root cause and improvment actions.