A Complete Guide to Die Casting: Types, Materials, and Applications

_1769416090_WNo_1600d900.webp)

Die casting plays a key role in modern manufacturing.

This guide explains die casting processes, materials, and applications, helping the following professionals produce accurate, durable, and cost-effective components:

- Engineers

- Product designers

- Industrial managers

- Metallurgists

- Manufacturing specialists

We’ll cover types, alloys, advantages, and applications, showing how to choose the right process for your projects. Keep reading to discover the best strategies for high-quality die casting.

Table of Contents

- What Is Die Casting

- Types of Die Casting

- Complete Die Casting Process

- Die Casting Materials

- Die Casting Advantages & Disadvantages

- Die Casting Applications

- Comparison

- How to Choose a Die Casting Process?

- Conclusion

What Is Die Casting

Die casting is a metal casting process in which molten metal is injected into a reusable steel mold (die) under high pressure. This process enables the production of complex metal parts with high dimensional accuracy, smooth surface finish, and excellent consistency. Die casting is widely used in high-volume manufacturing for industries such as automotive, electronics, aerospace, and industrial equipment.

Types of Die Casting

Die casting processes are mainly divided according to how the molten metal is injected into the mold. Choosing the right type affects production speed, part quality, and material suitability.

By Injection Method

The injection method describes the way molten metal enters the die. The two most common approaches are hot-chamber and cold-chamber die casting, each optimized for different metals and production requirements.

1.1 Hot-Chamber Die Casting

_1769416401_WNo_1600d900.webp)

Hot-chamber die casting is typically used for metals with low melting points. It allows for rapid cycles and efficient production of complex parts.

What is Hot-Chamber Die Casting

In hot-chamber die casting, the metal is melted inside a chamber that is part of the machine itself. This setup enables the plunger to quickly inject molten metal directly into the die cavity, making it ideal for high-speed manufacturing.

Hot-Chamber Die Casting Process

The process begins with molten metal filling the hot chamber. The plunger then moves downward, forcing the metal into the mold under high pressure, usually between 700 and 5,000 psi. Once the mold is filled, the metal solidifies, and the plunger returns to the starting position, ready for the next cycle. This continuous cycle allows for fast and consistent production of parts with fine details.

Advantages of Hot-Chamber Die Casting

Hot-chamber die casting is fast and efficient, producing high-quality parts with smooth surfaces and good dimensional accuracy. The method generates minimal waste and reduces energy consumption, making it environmentally friendly. Machines also tend to have a longer service life since only low-melting-point metals are used.

Disadvantages of Hot-Chamber Die Casting

This method is limited to low-melting-point metals. Porosity can occur if the process is not carefully controlled, and initial machine setup costs are relatively high. Overheating can damage the mold or metal surface, requiring careful temperature management.

1.2 Cold-Chamber Die Casting

Cold-chamber die casting is used for metals with higher melting points. The metal is melted in a separate furnace and poured into the machine, which reduces corrosion and allows the use of metals that cannot be processed in hot-chamber machines.

What is Cold-Chamber Die Casting

This process is ideal for copper, brass, zinc, aluminum, and their alloys. It provides greater control over metal temperature and is suitable for larger parts or metals that would damage a hot-chamber machine.

Cold-Chamber Die Casting Process

The molten metal is ladled into the shot chamber from an external furnace. The plunger then injects the metal into the die cavity under high pressure, typically between 2,000 and 20,000 psi. This separation allows for better handling of high-melting-point or corrosive metals.

Advantages of Cold-Chamber Die Casting

Cold-chamber die casting enables production of strong, precise, and durable parts. It allows for complex shapes, integral fasteners, and a wide range of finishing options. It is a flexible and economical solution for medium-to-high volume production.

Disadvantages of Cold-Chamber Die Casting

The cycle time is slightly longer than hot-chamber casting, and additional handling is required. The molten metal can oxidize or pick up impurities, which requires careful process control to maintain high quality.

By Pressure Method

Die casting can be classified according to the pressure applied during metal injection. Pressure affects metal flow, part density, and surface quality. The two main techniques are low-pressure and high-pressure die casting.

3.1 Low-Pressure Die Casting

Low-pressure die casting (LPDC) uses a gentle, controlled pressure to fill the mold cavity with molten metal. This continuous, regulated flow helps compensate for shrinkage during solidification and reduces defects like porosity or oxidation.

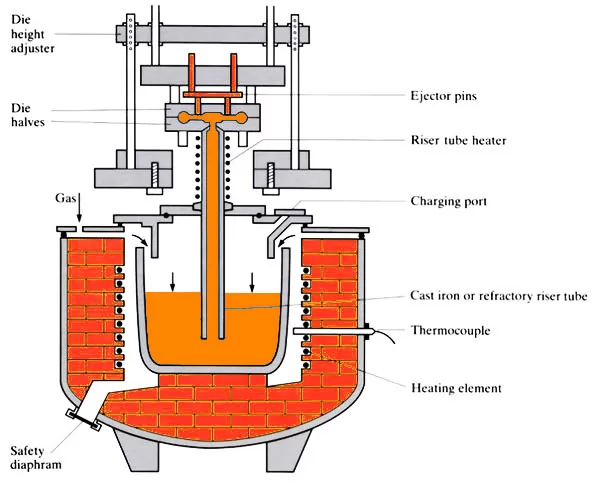

What is Low-Pressure Die Casting

In LPDC, molten metal is pushed into the die through a riser tube under a low pressure, usually around 2–15 psi. The process ensures a uniform metal distribution from top to bottom, creating high-precision and high-integrity parts.

Low-Pressure Die Casting Process

The process begins by melting the metal in a furnace until it reaches the casting temperature. The molten metal is then transferred to a holding chamber beneath the die. Low pressure forces the metal upward through the riser tube into the mold, filling it completely. Once solidification is complete, pressure is released and any excess metal is returned to the holding chamber for reuse. The mold is cooled, and the casting is removed.

Advantages of Low-Pressure Die Casting

LPDC offers excellent dimensional accuracy and uniformity. Castings have minimal defects and high density. This method also allows production of medium-to-large parts with consistent mechanical properties and reduced material waste.

Disadvantages of Low-Pressure Die Casting

The main drawbacks are slower production cycles due to the low pressure and potential equipment wear from repeated contact with molten metal. Additionally, LPDC is not suitable for extremely thin-walled parts, as the method requires a minimum wall thickness for reliable filling.

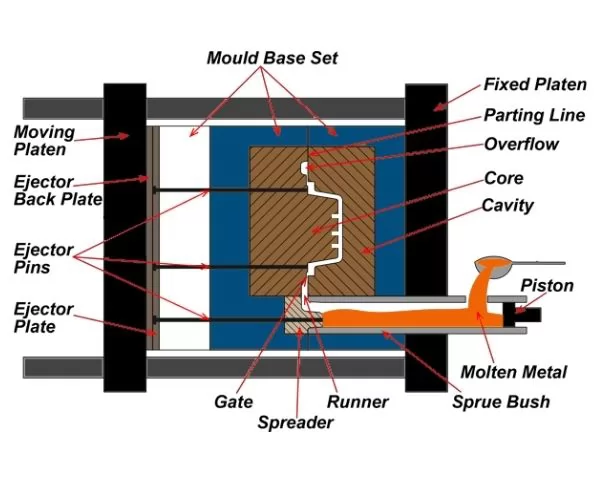

3.2 High-Pressure Die Casting

High-pressure die casting (HPDC) forces molten metal into a closed steel mold under high pressure. This method is ideal for producing detailed, thin-walled components rapidly and in large quantities.

What is High-Pressure Die Casting

In HPDC, the molten metal is injected at high pressure into a die cavity and held in place until it solidifies. This ensures precise dimensions, smooth surfaces, and excellent mechanical properties. It is commonly used for metals like aluminum, zinc, and magnesium.

High-Pressure Die Casting Process

The molten metal is forced into a die mounted on a hydraulic press. The machine holds the die closed during solidification, and the metal quickly takes the shape of the mold. Both stationary and moving halves of the die are used, allowing intricate designs to be formed efficiently.

Advantages of High-Pressure Die Casting

HPDC is highly productive and cost-effective for large-scale manufacturing. It produces strong, lightweight components with tight tolerances, smooth surfaces, and minimal need for additional machining. Complex shapes can be formed in a single step, reducing assembly requirements.

Disadvantages of High-Pressure Die Casting

The main challenge is potential porosity, which can affect post-casting heat treatment. Surface defects like blisters may appear if not carefully controlled. However, high tooling costs are offset by the ability to produce large volumes efficiently, lowering unit cost in mass production.

By Metal Filling Method

The way molten metal fills the die cavity can greatly influence the casting’s quality, density, and surface finish. Common methods include gravity casting, vacuum-assisted casting, squeeze casting, and semi-solid casting, each suitable for different applications and materials.

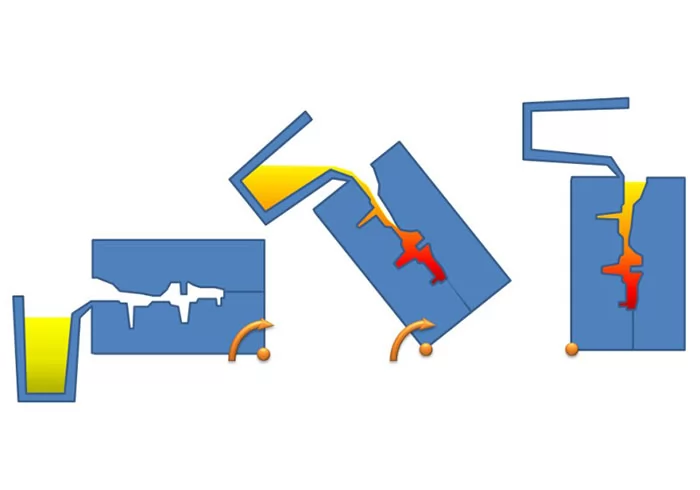

4.1 Gravity Die Casting

Gravity die casting uses the force of gravity alone to pour molten metal into a reusable steel or metal mold. By tilting the die, operators can control the flow rate and direction of the metal. Sand cores may be added to create undercuts or hollow features. This method is ideal for medium-to-large parts and produces dense castings with smooth surfaces.

Gravity Die Casting Process

The process begins with a heated die coated with a refractory layer to improve heat distribution and facilitate part removal. Molten metal is poured into the cavity using a ladle, either manually or automatically in high-volume production. Once the metal solidifies, the die is opened, and the casting is removed, cleaned, and finished by trimming gates, runners, and any excess material.

Advantages of Gravity Die Casting

Gravity die casting produces strong, dense parts with excellent mechanical properties. It is well-suited for automated production, can accommodate complex shapes with cores, and typically requires minimal post-processing.

Disadvantages of Gravity Die Casting

Production rates are lower than high-pressure die casting for some metals, and tooling costs are higher than sand casting. It is also less suitable for very thin-walled parts, generally limited to walls thicker than 3–5 mm.

4.2 Vacuum Die Casting

_1769416913_WNo_1600d900.webp)

Vacuum die casting improves part integrity by removing air and gases from the die cavity before metal injection. This reduces porosity and surface defects, making it ideal for thin-walled or precision components.

Vacuum Die Casting Process

First, a vacuum is created in the die cavity using a vacuum pump. Molten metal is then injected into the evacuated mold, filling all cavities uniformly. After solidification, the part is ejected, resulting in dense castings with minimal surface flaws.

Advantages of Vacuum Die Casting

This process significantly reduces porosity and surface defects like blowholes or blisters. It produces stronger, denser components with high dimensional accuracy and allows for the production of thinner or more intricate parts.

Disadvantages of Vacuum Die Casting

Vacuum die casting requires precise tooling and careful mold maintenance. Complex parts may need additional preparation, and the method can be sensitive to operational errors, increasing production cost.

4.3 Squeeze Die Casting

_1769416986_WNo_1600d900.webp)

Squeeze die casting combines aspects of casting and forging. Molten metal is poured into a heated die and then compressed under hydraulic pressure, improving density and reducing porosity.

Squeeze Die Casting Process

Molten metal is added to the die, which is preheated and coated with a release agent. Hydraulic pressure is applied before and during solidification, ensuring uniform filling and minimizing internal defects. Once solidified, the die is opened and the casting is ejected.

Advantages of Squeeze Die Casting

It produces high-strength parts with fine microstructure, excellent surface finish, and near-net shapes that require little post-machining. Material usage is optimized with minimal waste.

Disadvantages of Squeeze Die Casting

Tooling and equipment costs are high, and production is less flexible due to specialized dies. The process requires precise control, which can increase cycle times and overall cost.

4.4 Semi-Solid Die Casting

_1769417047_WNo_1600d900.webp)

Semi-solid die casting (SSM) uses metal in a partially solid, thixotropic state, combining the flow characteristics of liquid metal with the mechanical benefits of solid metal. This method enables precise, near-net-shape parts with minimal porosity.

Semi-Solid Die Casting Process

Metal is partially melted to maintain 50–70% solid content. The slurry is injected into a die, where it fills the cavity smoothly and solidifies with a refined microstructure. Techniques include thixocasting, rheocasting, thixomolding, and strain-induced methods.

Advantages of Semi-Solid Die Casting

SSM produces high-quality, dense castings with fine microstructures and strong mechanical properties. The process is environmentally friendly, reduces material waste, and is suitable for high-performance parts.

Disadvantages of Semi-Solid Die Casting

Equipment costs are higher than conventional die casting, and precise temperature control is critical. Specialized machinery is required, which increases initial investment and operational complexity.

Complete Die Casting Process

The complete die casting process involves multiple steps, from mold preparation to final finishing. Each stage is crucial to ensure high-quality castings with accurate dimensions and excellent surface finish.

Mold Design and Preparation

Before casting begins, the die must be designed and prepared. This includes heating the mold to the optimal temperature and applying a release agent or refractory coating. The coating helps maintain consistent mold temperature, delays premature solidification, and allows easy removal of the casting once it has solidified. The die halves are then securely clamped together in preparation for casting.

Metal Melting and Temperature Control

Metal alloys are melted in a furnace to the appropriate casting temperature. Continuous monitoring ensures that the molten metal remains at the correct temperature for uniform flow and proper filling. Maintaining precise temperature control reduces defects and improves part consistency.

Metal Injection and Filling

The molten metal is introduced into the die cavity. Depending on the method, this can be done manually with a ladle or automatically with an injection system. Gravity or controlled pressure guides the metal to fill the mold completely, minimizing turbulence and reducing porosity.

Solidification and Cooling

After filling, the metal is allowed to solidify within the mold. Adequate cooling time is critical to prevent deformation or shrinkage defects. Controlled solidification ensures the casting accurately reproduces the mold geometry.

Ejection and Demolding

Once solidified, the die halves are unclamped and opened, and the casting is carefully ejected. Ejection can be done manually or with the help of ejector pins. Proper handling at this stage prevents damage to the part.

Trimming and Post-Processing

Excess material such as gates, runners, sprues, and flash is removed. Additional finishing operations, like smoothing sharp edges, polishing, or minor machining, may also be performed to achieve the desired component specifications.

Surface Treatment

Optional surface treatments, such as coating, plating, or painting, are applied depending on the part requirements. These treatments enhance corrosion resistance, improve aesthetics, and provide additional functional properties.

Die Casting Materials

The choice of material is critical in die casting, as it affects the casting process, mechanical properties, and final application. Common metals include aluminum, zinc, magnesium, and copper alloys, each offering unique advantages.

Aluminum

Aluminum is often alloyed with silicon or copper to improve hardness, fluidity, and resistance to cracking during casting. Its excellent dimensional stability makes it suitable for producing thin-walled and complex parts. Aluminum castings are widely used in applications requiring corrosion resistance and thermal or electrical conductivity.

Zinc

Zinc has good strength at room temperature and is easy to cast, making it ideal for precise, medium-strength components. It is especially compatible with hot-chamber die casting due to its relatively low melting point. Zinc is commonly used for connectors, gears, and other parts where accuracy and durability are important.

Magnesium

Magnesium is a lightweight metal with a high strength-to-weight ratio, making it suitable for thin-walled and precision parts. Its low density helps reduce overall component weight, and it is often chosen for applications where both strength and lightness are required.

Copper and Copper Alloys

Copper-based alloys are highly durable and resistant to corrosion. They are commonly used for plumbing, electrical components, and mechanical parts that require high strength and long-term reliability.

Die Casting Advantages & Disadvantages

Die casting has distinct benefits and limitations. Understanding these helps in selecting the right process for each application.

Advantages

- High Precision: Parts can be produced with tight tolerances and accurate dimensions.

- Good Surface Finish: Castings have smooth surfaces that often require minimal post-processing.

- High Production Efficiency: Suitable for large-scale manufacturing with fast cycle times.

- Thin-Wall Capability: Allows creation of complex shapes with thin sections without compromising strength.

Disadvantages

- High Tooling Cost: Dies and machinery are expensive, making low-volume production less economical.

- Porosity Risk: Trapped gases can form cavities, affecting strength and surface quality.

- Material Limitations: Mainly suitable for non-ferrous metals; high-melting-point alloys can reduce die life.

Die Casting Applications

Die casting is widely used for producing large volumes of identical components with high precision and consistency. The process is especially suited for lightweight, thin-walled parts, making it popular across multiple industries.

Automotive Industry

Die cast components are extensively used in vehicles, including engine blocks, cylinder heads, wheels, manifolds, and structural parts. Using aluminum and other light metals reduces overall vehicle weight, improving fuel efficiency and performance.

Aerospace

The aerospace sector benefits from die casting for lightweight, high-strength components. Parts such as brackets, housings, and structural elements are manufactured to precise tolerances while maintaining durability under demanding conditions.

Consumer Electronics

Die casting produces housings, frames, and internal components for electronics like laptops, smartphones, and cameras. The process allows for intricate designs, thin walls, and high surface quality, meeting both functional and aesthetic requirements.

Industrial Equipment

Machinery and power tools use die cast parts for gears, housings, and mechanical supports. High accuracy and consistent material properties ensure reliability and longevity in demanding industrial applications.

Medical Devices

Medical instruments and devices employ die casting for precise, lightweight components that meet strict regulatory standards. Aluminum and copper alloys are often chosen for their biocompatibility and corrosion resistance.

Comparison

The table below summarizes the key differences between die casting and other common manufacturing processes, highlighting strengths, limitations, and suitable applications.

| Process | Advantages | Limitations | Best Use |

|---|---|---|---|

| Die Casting | High precision, smooth surface, fast mass production, thin-walled parts possible | High tooling cost, limited to non-ferrous metals, less flexible for small batches | Automotive components, electronics housings, industrial parts |

| Sand Casting | Flexible for large/irregular shapes, low tooling cost | Lower dimensional accuracy, rougher surface, slower production | Large parts, low-volume production, prototypes |

| Investment Casting | Excellent surface finish, capable of very intricate shapes | Slower process, higher cost per part, less efficient for mass production | Complex, high-precision components in small-to-medium quantities |

| CNC Machining | High accuracy, versatile for many materials, minimal tooling setup | Material wastage, slower for large volumes, costly for complex 3D shapes | Prototypes, low-volume production, critical tolerance parts |

How to Choose a Die Casting Process?

Choosing the right die casting process is essential to achieve high-quality parts efficiently and cost-effectively. Decisions should be based on part design, material, production volume, and the balance between cost, performance, and manufacturability.

1. Part Design

The geometry and complexity of the component heavily influence which die casting method is most suitable. Thin walls, intricate features, or undercuts may require processes such as high-pressure, semi-solid, or vacuum die casting to ensure accurate dimensions and minimal defects. Simpler parts may be efficiently produced using gravity or low-pressure die casting.

2. Material Selection

The type of metal dictates the die casting options available. Aluminum, zinc, magnesium, and copper alloys each have unique flow properties, melting points, and mechanical characteristics. Aluminum is ideal for lightweight, corrosion-resistant parts, while zinc is suitable for high-precision small components. Material choice affects die wear, cycle times, and potential post-processing requirements.

3. Production Volume

High-volume manufacturing favors processes like high-pressure die casting due to fast cycle times and minimal labor. Low-volume or prototype production may benefit from gravity or vacuum die casting, which have lower tooling costs and greater flexibility. Understanding the intended production scale helps optimize cost-efficiency and equipment utilization.

4. Cost and Performance Balance

Decisions should consider both upfront tooling costs and part performance requirements. Some die casting methods, such as high-pressure or semi-solid casting, require higher initial investment but offer superior surface finish, strength, and dimensional accuracy. Others may reduce cost but limit part complexity or wall thickness. Balancing cost, quality, and functional performance is key to selecting the optimal process.

5. Additional Considerations

Other factors include tolerance requirements, surface finish, post-processing needs, and environmental or energy constraints. For example, parts requiring tight tolerances or high cosmetic quality may favor vacuum or semi-solid processes. Meanwhile, parts intended for mass production in automotive or electronics applications may prioritize cycle time and efficiency over tooling cost.

Conclusion

Die casting is a highly efficient and versatile metal casting process, capable of producing complex, high-precision components with smooth surfaces and consistent mechanical properties. Various die casting methods—hot-chamber, cold-chamber, high-pressure, low-pressure, gravity, vacuum, squeeze, and semi-solid—are suited to different metals, part designs, and production requirements. Common materials include aluminum, zinc, magnesium, and copper alloys, each offering unique advantages for strength, weight, corrosion resistance, and dimensional stability.

The process provides fast production, excellent repeatability, and the ability to create thin-walled or intricate parts, making it widely used in automotive, aerospace, consumer electronics, industrial machinery, and medical applications. However, it involves higher tooling costs, material limitations, and potential porosity risks. Selecting the optimal die casting method depends on part geometry, material properties, production volume, cost-performance trade-offs, and additional requirements such as tolerance, surface finish, and environmental considerations, ensuring high-quality, cost-effective manufacturing outcomes.

-

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026 -

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World -

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China -

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

-

Jan 30, 2026Aluminum Die Casting Cost Breakdown: From Material to Machining

Jan 30, 2026Aluminum Die Casting Cost Breakdown: From Material to Machining -

Jan 28, 2026Top 10 Zinc Pressure Die Casting Manufacturers and Suppliers in the World

Jan 28, 2026Top 10 Zinc Pressure Die Casting Manufacturers and Suppliers in the World -

Jan 28, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026

Jan 28, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026 -

Jan 26, 2026A Complete Guide to Die Casting: Types, Materials, and Applications

Jan 26, 2026A Complete Guide to Die Casting: Types, Materials, and Applications