Top 10 Aluminium Casting Companies and Foundries in the World

_1761543299_WNo_1600d900.webp)

Are you searching for reliable, high-quality aluminium casting companies for your next project? What truly separates the industry leaders from the rest? And with so many aluminium casting foundries worldwide, how do you identify the partners that can deliver on precision, scale, and innovation?

This article cuts through the noise to provide a definitive guide to the top 10 aluminium casting companies and foundries globally. We have meticulously evaluated these manufacturers based on key criteria including their technical capabilities, industry specializations, quality certifications, production capacity, and proven track record. Whether your needs involve sand casting, die casting, or permanent mold processes, this curated list offers a clear overview of the best partners for aerospace, automotive, industrial, and defense applications, giving you the essential information to make an informed decision.

By exploring the strengths and specializations of these premier suppliers, this guide aims to connect you with the ideal manufacturing partner for your specific requirements; read on to discover which foundry can best bring your designs to life.

List of the Aluminium Casting Companies and Foundries in the World

List of the Aluminium Casting Companies and Foundries in the World

| Brand | Headquarters | Main Products/Services |

|---|---|---|

| 1. Olson Aluminum Castings | Rockford, IL, USA | Custom sand cast aluminum components, Prototype casting, Engineering services |

| 2. Wisconsin Aluminum Foundry (WAF) | Manitowoc, WI, USA | Permanent mold casting, Green sand casting, Low pressure processes, Machining |

| 3. Boose Aluminum Foundry Co., Inc. (BAF) | Stevens, PA, USA | Aluminum sand castings, Military/medical components, Product development |

| 4. Le Sueur Incorporated | Le Sueur, MN, USA | Permanent mold, Die casting, Sand casting, Precision machining |

| 5. CaneKast | Clinton, SC, USA | Non-ferrous casting solutions, Green sand, No-bake processes, Rapid production |

| 6. Alcast Company | Peoria, IL, USA | Permanent mold castings, Electromagnetic technology, CNC machining |

| 7. Aluminum Castings Company LLC | Galesburg, IL, USA | Aluminum sand castings, Complex cored components, Value-added services |

| 8. Bremer Manufacturing Company, Inc. | Elkhart Lake, WI, USA | Aluminum sand castings, CNC machining, Heat treatment, Assembly solutions |

| 9. US Aluminum Castings | Entiat, WA, USA | Precision castings for aerospace/defense, Nadcap heat treat, Tooling design |

| 10. NINGBO INNOVAW MECHANICAL CO., LTD | Ningbo, China | High pressure die casting, Low pressure casting, CNC machining, Surface finishing |

1. Olson Aluminum Castings

Introduction:

Olson Aluminum Castings operates as a distinguished aluminium casting foundry and manufacturer, specializing in custom sand cast aluminum components for a diverse range of industrial applications. This aluminium casting company has built a reputation for producing industrial-grade, pressure-tight, and leak-free castings that boast superior machining properties and excellent surface finishes. As a reliable aluminium casting supplier, they are committed to providing some of the shortest production lead times in the industry, making them an ideal manufacturing partner for projects requiring both exceptional quality and rapid turnaround.

The aluminium casting factory is ISO 9001:2015 registered, underscoring its dedication to high industry standards in efficiency, operational controls, and manufacturing processes. Olson Aluminum Castings serves as a full-service aluminium casting manufacturer, offering comprehensive services from prototype development and casting engineering to high-quality pattern start-ups. Their team excels at handling challenging projects that demand exceptional quality and value, focusing on the technical requirements rather than just the project size, which makes them a preferred choice for businesses seeking a specialized and responsive aluminium casting partner.

Established: 1945

Headquarters: 2135 15th Street, Rockford, Illinois 61104, USA

Main Products/Services:

- Custom sand cast aluminum components

- Prototype casting development

- Pressure-tight and leak-free castings

- Engineering and pattern start-up services

- Industrial-grade aluminum castings for various sectors

2. Wisconsin Aluminum Foundry (WAF)

Introduction:

Wisconsin Aluminum Foundry (WAF) is a premier non-ferrous aluminum casting manufacturer and foundry with over 115 years of industry expertise. As a leading aluminum casting company, WAF specializes in producing high-quality custom aluminum, bronze, and brass castings for demanding industrial applications. Their vertically integrated operations encompass in-house tooling, heat treating, impregnation, and machining capabilities, allowing them to maintain strict quality control throughout the manufacturing process.

This aluminum casting foundry serves as a trusted supplier for OEMs across multiple industries, including heavy-duty truck, automotive, marine, oil & gas, agriculture, defense, and medical sectors. WAF distinguishes itself through its industry-leading on-time delivery performance, world-class lead times, and exceptional quality standards. The company operates multiple manufacturing facilities across the Midwest, equipped with advanced casting technologies to handle both prototype development and high-volume production requirements.

Established: 1909

Headquarters: 838 S. 16th Street, Manitowoc, WI 54220, USA

Main Products/Services:

- Permanent mold aluminum casting

- Green sand casting

- Air set sand casting

- Low pressure permanent mold processes

- DISA and Hunter molding technologies

- Complete machining and value-added services

3. Boose Aluminum Foundry Co., Inc. (BAF)

Introduction:

Boose Aluminum Foundry Co., Inc. (BAF) is a fourth-generation family-owned aluminum sand casting foundry with a rich history dating back to 1933. As a trusted aluminum casting manufacturer, BAF specializes in producing high-quality American-made aluminum sand castings for demanding industries including military, defense, medical, robotics, power generation, and commercial sectors. The foundry takes pride in building long-term customer relationships through exceptional service and reliable delivery of precision castings.

This aluminum foundry stands out for its commitment to quality and customer partnership, operating with the philosophy that "What We Do Here Matters." BAF is ISO certified and ITAR registered, demonstrating its capability to meet stringent military and defense specifications. The company's product development team works closely with customers to design tooling and develop sound manufacturing processes for each project, ensuring successful product launches and optimal casting solutions.

Established: 1933

Headquarters: 77 N Reamstown Road, Stevens, PA 17578, USA

Main Products/Services:

- Aluminum sand castings

- Military specification castings

- Medical equipment components

- Robotics and automation parts

- Power generation components

- Product development and tooling design

4. Le Sueur Incorporated

Introduction:

Le Sueur Incorporated stands as a premier aluminium casting manufacturer and supplier with a rich history dating back to 1946. This aluminium casting foundry specializes in producing dimensionally complex, pressure-tight aluminum castings for diverse industrial applications. As a full-service aluminium casting company, they offer comprehensive solutions including permanent mold casting, die casting, and sand casting processes, providing clients with unbiased recommendations for their specific project requirements.

The aluminium casting factory operates from a 274,000-square-foot manufacturing facility equipped with state-of-the-art technology for aluminum casting production, precision machining, and quality control. Their engineering team engages early in the design process to help clients select the optimal aluminum casting method, alloy, and finishing processes. The company's capabilities extend to custom aluminum casting solutions, making them an ideal partner for businesses seeking reliable aluminum casting suppliers for both prototype development and high-volume production runs.

Established: 1946

Headquarters: 1409 Vine Street, Le Sueur, Minnesota 56058-0149, USA

Main Products:

- Permanent mold aluminum castings

- Die casting aluminum components

- Sand casting aluminum parts

- Precision machining services

- Custom aluminum casting solutions

5. CaneKast

Introduction:

CaneKast™ is revolutionizing the non-ferrous casting industry through its coast-to-coast network of specialized foundries and manufacturing facilities. As a consolidator of small-to-medium aluminum casting companies, CaneKast combines decades of artisanal foundry expertise with cutting-edge technology to deliver precision aluminum castings with unmatched efficiency. Their unique business model preserves the personalized service of family-owned foundries while implementing industrial-scale production capabilities, making them an ideal partner for both prototype development and high-volume aluminum casting production.

This innovative aluminum casting company operates multiple strategically located facilities across the United States, each specializing in different casting processes including green sand, no-bake/air-set, and permanent mold casting. CaneKast's recent acquisition of Southern Aluminum Foundry & Machine and installation of the revolutionary DISA® MATCH 24/28 system demonstrates their commitment to advancing aluminum casting technology, achieving production speeds ten times faster than traditional methods while maintaining exceptional quality standards for pressure-tight and dimensionally complex castings.

Established: 2020

Headquarters: 385 Torrington Rd, Clinton, SC 29325, USA

Main Products/Services:

- Non-ferrous aluminum casting solutions

- Green sand casting production

- No-bake/air-set casting processes

- Gravity-fed die-cast/permanent mold casting

- Associated services (CNC machining, heat treating, prototyping)

- Rapid production through DISA MATCH technology

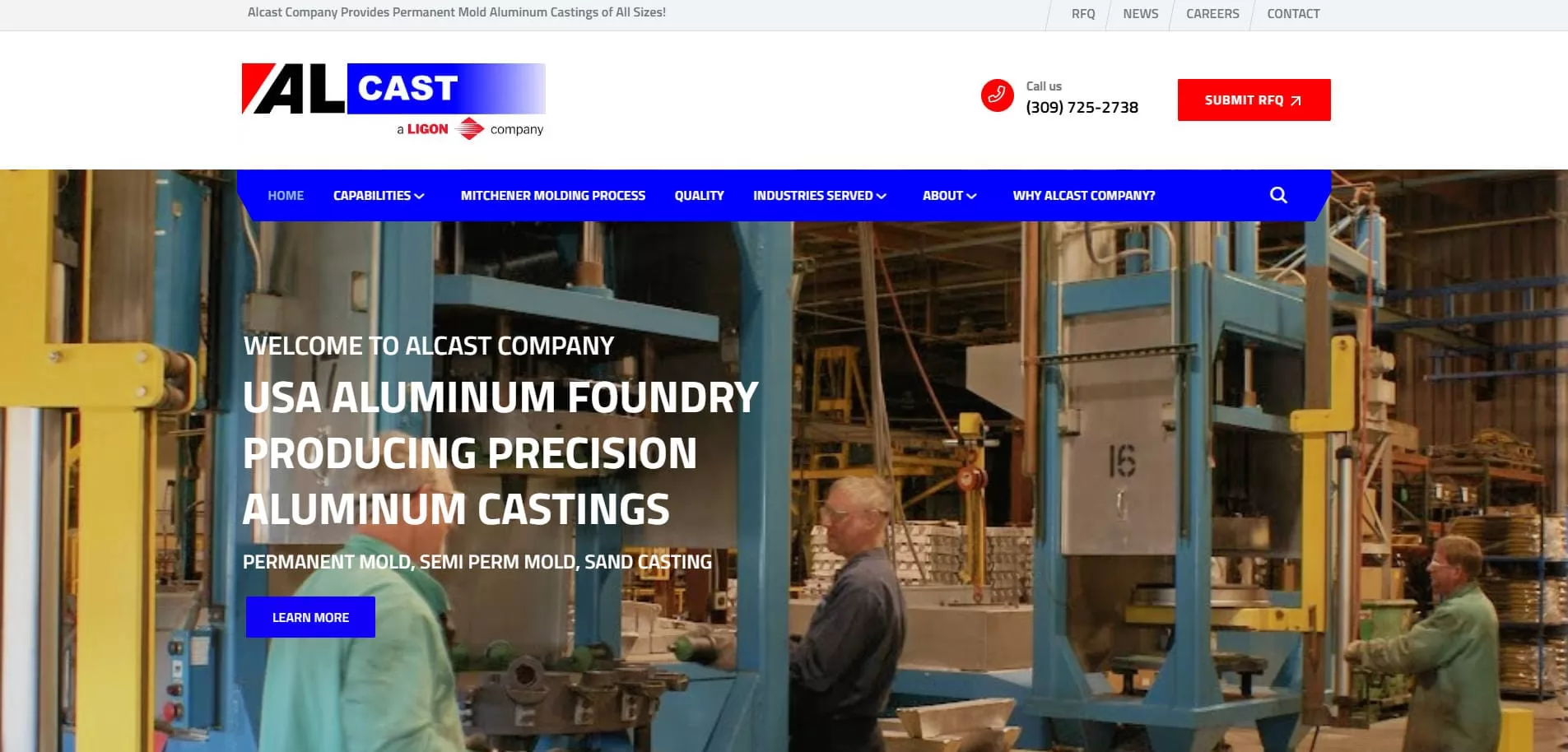

6. Alcast Company

Introduction:

Alcast Company operates as a specialized aluminium casting manufacturer with a distinguished history spanning five decades in the American foundry industry. This aluminium casting company has established itself as a reliable aluminium casting supplier through its certified ISO 9001:2015 quality management system and proprietary electromagnetic permanent mold technology. The aluminium casting foundry's expertise focuses on producing high-integrity, pressure-tight components that meet rigorous industrial standards, while its comprehensive service approach encompasses everything from initial design consultation to final machining. As an established aluminium casting manufacturer, the company serves diverse sectors with customized solutions that leverage both traditional foundry expertise and innovative casting methodologies.

The aluminium casting factory maintains extensive manufacturing capabilities within its 278,000-square-foot Illinois facility, equipped with specialized Mitchener Molding Machines and complete CNC machining operations. This aluminium casting manufacturer demonstrates remarkable flexibility in production volumes, handling everything from small prototype runs to mass production exceeding half a million components annually. The foundry's technical capabilities allow it to produce aluminium castings across an impressive weight spectrum, from lightweight precision parts to substantial components over 350 pounds. As a full-service aluminium casting company, Alcast provides clients with integrated manufacturing solutions that ensure quality control and cost efficiency at every production stage, from molten metal to finished machined product.

Established: 1970

Headquarters: 8821 N University St, Peoria, IL 61615, USA

Main Products:

- Permanent mold aluminum castings

- Electromagnetic casting technology solutions

- Precision CNC machined components

- Complex pressure-tight aluminum parts

- Custom aluminum casting development

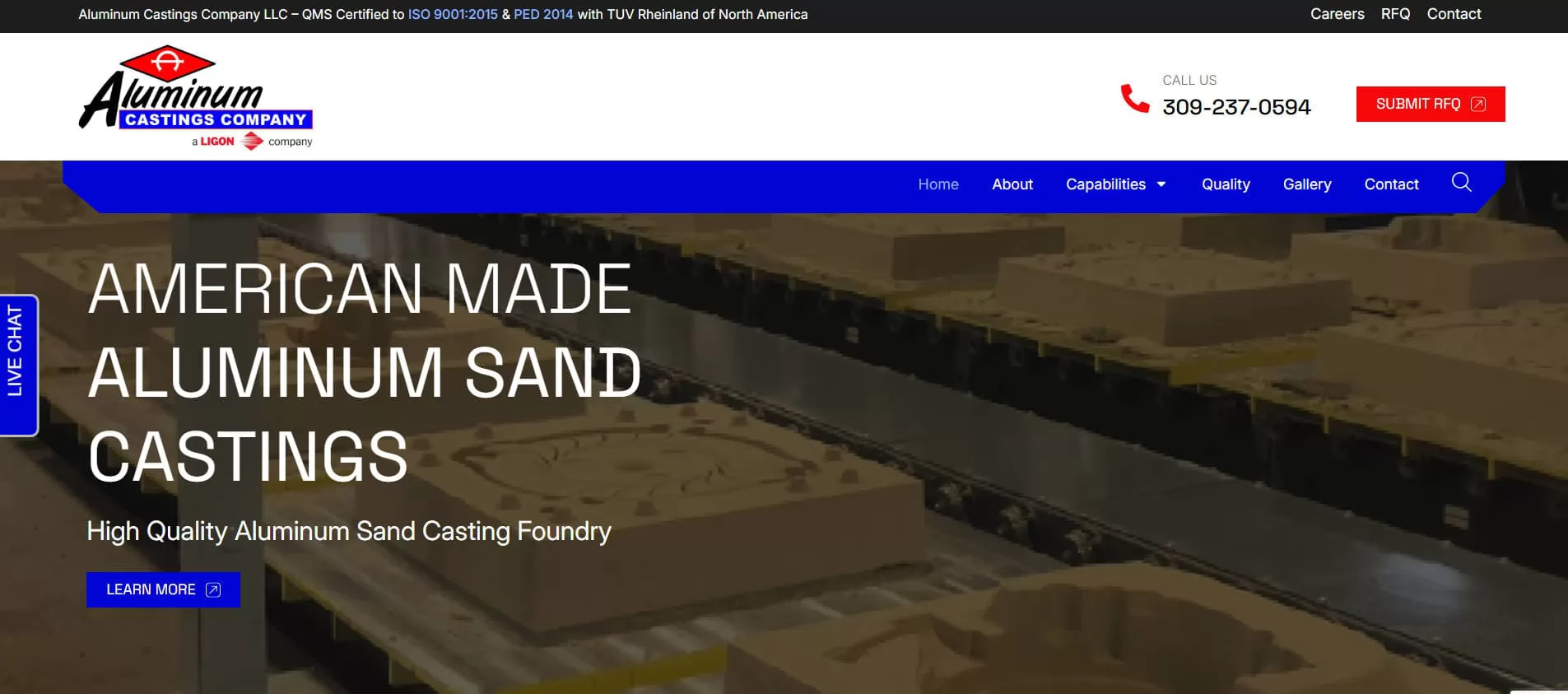

7. Aluminum Castings Company LLC

Introduction:

Aluminum Castings Company LLC operates as a specialized aluminum sand casting foundry with over 60 years of continuous operation in Galesburg, Illinois. This aluminum casting manufacturer has built its reputation on producing high-quality sand castings using both green sand and air-set/no-bake molding processes. As a subsidiary of Alcast Company, this aluminum casting supplier offers comprehensive capabilities from prototype development to high-volume production, serving industries that require complex, cored aluminum components with precise dimensional tolerances.

The aluminum casting factory spans 25,000 square feet and features advanced DISA automated molding systems and Kloster air-set molding equipment capable of handling castings up to 12 feet long and 4 tons in weight. This aluminum casting company maintains strict quality control through ISO 9001:2015 certification and in-house spectrometer testing, ensuring material integrity across multiple aluminum alloys including Almag 35, Tenzaloy 713, and A356 series. The foundry's integrated operations encompass core making, melting, casting, finishing, and value-added services, positioning it as a complete aluminum casting solution provider for demanding industrial applications.

Established: 1964

Headquarters: 340 South Kellogg Street, Galesburg, IL 61401-4918, USA

Main Products/Services:

- Aluminum sand castings (green sand & air-set/no-bake)

- Complex cored components

- Prototype to production volume casting

- Shell core, cold box, and oil sand core processes

- Value-added finishing and machining services

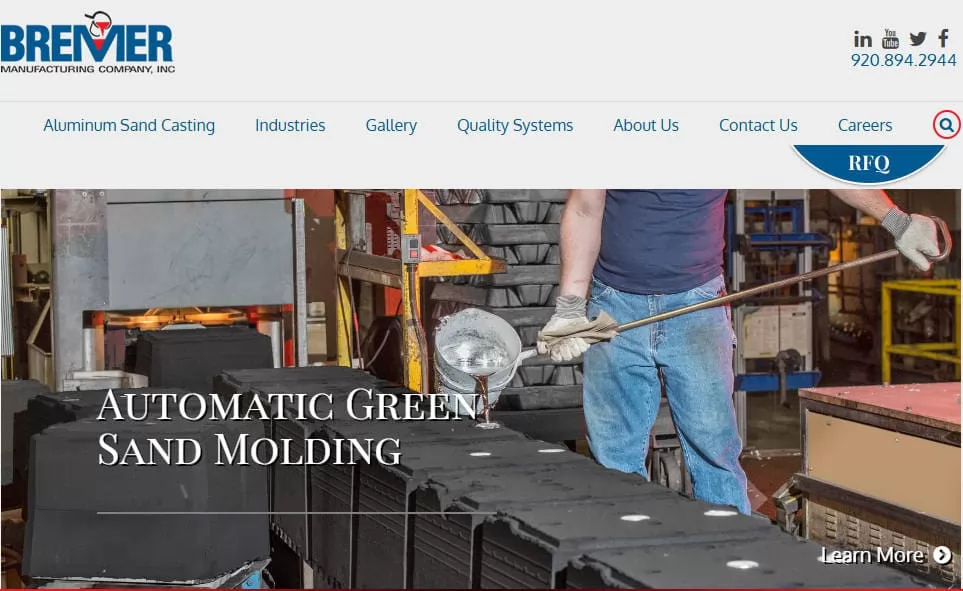

8. Bremer Manufacturing Company, Inc.

Introduction:

Bremer Manufacturing Company stands as a heritage aluminum sand casting foundry with over 85 years of continuous operation in Wisconsin's manufacturing heartland. This family-owned aluminum casting manufacturer has evolved from its 1937 origins producing agricultural implements to become a trusted aluminum casting supplier for demanding industrial applications. The aluminum casting factory combines time-tested foundry expertise with modern automated equipment to deliver precision sand castings ranging from a few ounces to 125 pounds, serving as a critical aluminum casting company for engine manufacturers and metalworking industries across North America.

The 66,300-square-foot aluminum casting foundry facility operates with ISO 9001:2015 certification and ITAR registration, implementing both automatic green sand molding and flexible air-set processes to accommodate diverse production needs. As an integrated aluminum casting manufacturer, Bremer provides comprehensive solutions encompassing in-house core making, heat treating, CNC machining, and final assembly. Their team of seasoned engineers - averaging over 15 years of experience - collaborates closely with clients to optimize designs for manufacturability, ensuring this Wisconsin-based aluminum casting supplier delivers quality components with industry-leading responsiveness.

Established: 1937

Headquarters: W2002 County Road Q, Elkhart Lake, WI 53020, USA

Main Products/Services:

- Aluminum sand castings (green sand & air-set processes)

- Complex cored components

- Precision CNC machining services

- Heat treatment and finishing

- Complete casting-to-assembly solutions

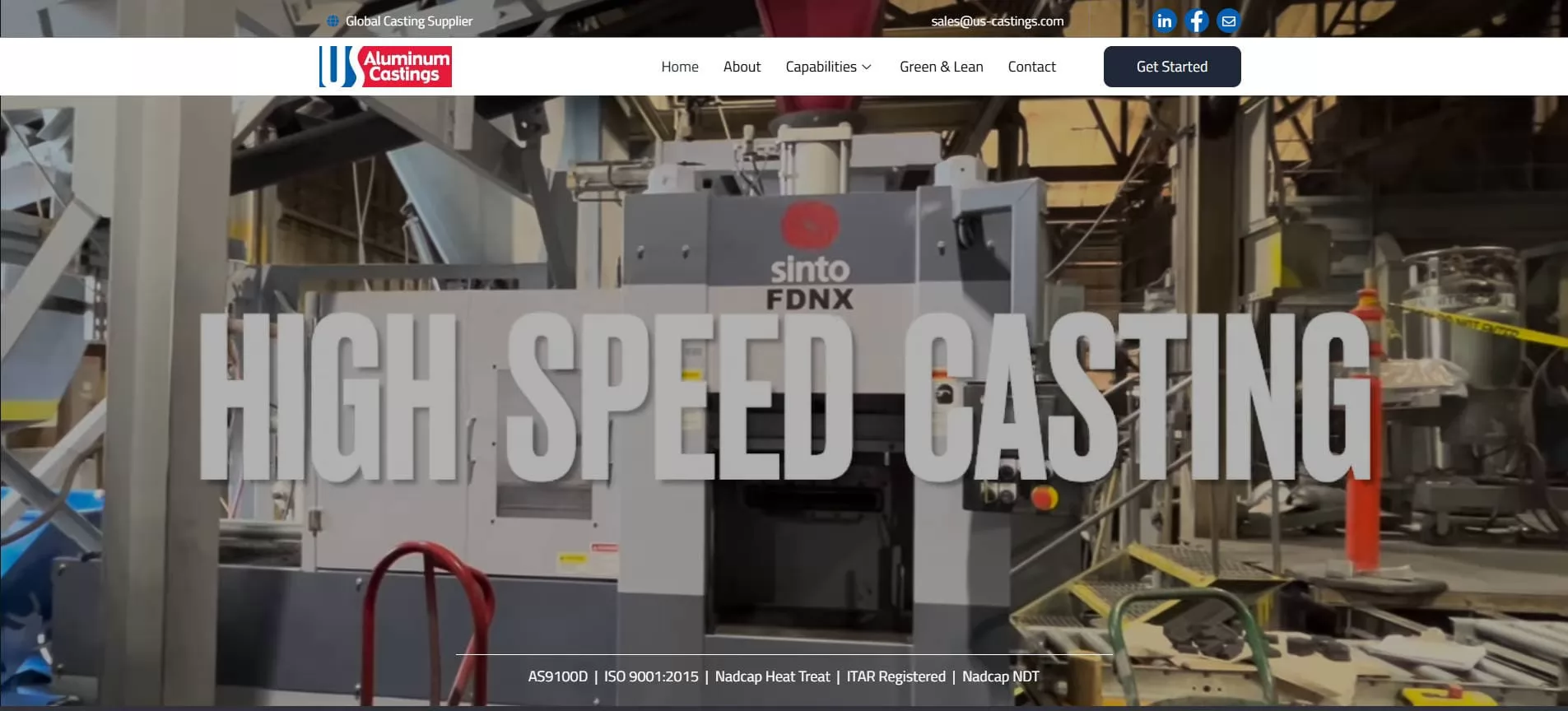

9. US Aluminum Castings

Introduction:

US Aluminum Castings operates as a premier precision aluminum casting supplier with over 114 years of continuous foundry operation, establishing itself as one of North America's most experienced aluminum casting manufacturers. This AS9100D and ISO 9001:2015 certified aluminum casting company specializes in high-reliability components for demanding aerospace, defense, and heavy truck applications. The aluminum casting foundry's comprehensive capabilities span multiple casting processes including permanent mold, dry sand, and green sand methods, supported by Nadcap-accredited heat treatment and non-destructive testing facilities.

The 100,000-square-foot aluminum casting factory in Entiat, Washington leverages renewable hydroelectric power and modern manufacturing technologies to produce over 425,000 castings annually. As a full-service aluminum casting manufacturer, USAC provides complete vertical integration with in-house tooling creation, precision machining, powder coating, and assembly services. Their engineering team collaborates closely with clients to optimize designs for manufacturability, ensuring this veteran aluminum casting supplier delivers mission-critical components with exceptional quality control and reliable delivery schedules for global customers.

Established: 1909

Headquarters: 14351 Shamel St., Entiat, WA 98822, USA

Main Products/Services:

- Precision aluminum castings for aerospace/defense

- Permanent mold, dry sand, and green sand casting

- Nadcap-accredited heat treatment and NDT

- Complete machining and finishing services

- Tooling design and manufacturing

10. NINGBO INNOVAW MECHANICAL CO., LTD

Introduction:

Innovaw has established itself as a leading aluminum die casting manufacturer and comprehensive metal component solutions provider since 1998. This IATF 16949 and ISO 9001:2015 certified aluminum casting company operates multiple specialized foundries across China, offering complete vertical integration from rapid prototyping to mass production. With expertise spanning high pressure die casting, low pressure casting, gravity casting, and precision CNC machining, Innovaw serves as a trusted aluminum casting supplier for global clients in automotive, aerospace, marine, and industrial sectors.

The aluminum casting factory combines 20+ years of technical expertise with modern manufacturing infrastructure, including advanced mold flow simulation, automated production lines, and rigorous quality control systems. As a full-service aluminum casting manufacturer, Innovaw's engineering team provides complete DFM support and APQP process management, ensuring optimal solutions for complex component requirements. Their 580+ employee workforce maintains exceptional quality standards with first-pass yield exceeding 99%, supported by Nadcap-accredited testing capabilities and comprehensive PPAP documentation.

Established: 1998

Headquarters: 904-905 China-base Building, No.666 Tiantong South Road, Ningbo 315100, China

Main Products/Services:

- Aluminum/zinc high pressure die casting

- Low pressure and gravity casting

- Precision CNC machining services

- Custom mold design and tooling

- Complete surface finishing solutions

Why Are Aluminium Casting Companies So Important?

Below we outline the main reasons aluminium casting companies and foundries play a vital role in global manufacturing — read on for the details.

Aluminium casting companies are a cornerstone of modern industry, supplying lightweight, durable, and cost-effective metal components for automotive, aerospace, construction, electronics, and machinery sectors. Across the world, aluminium foundries are trusted for their ability to deliver complex shapes, tight tolerances, and scalable production.

Lightweight and high strength: Aluminium castings provide an excellent strength-to-weight ratio, helping manufacturers reduce overall product weight while maintaining structural integrity.

Design flexibility: Casting processes allow intricate geometries that are difficult or expensive to achieve with machining or fabrication.

Cost efficiency: Aluminium is abundant and recyclable, enabling foundries to offer competitive pricing for both low- and high-volume production.

Corrosion resistance: Natural oxide layers and alloying options make aluminium castings suitable for harsh environments.

Where Are Leading Aluminium Casting Companies and Foundries Located?

The regions below are known globally for housing experienced aluminium casting manufacturers with advanced production capabilities.

Aluminium foundries operate worldwide, supporting diverse industries with gravity casting, high-pressure die casting, low-pressure casting, sand casting, and investment casting. Companies often source globally to balance quality, cost, and lead time.

- United States (Michigan, Ohio, California, Wisconsin)

- Germany

- Italy

- China

- India

- Japan

- South Korea

- Mexico

- Turkey

These regions host aluminium foundries specializing in automotive components, industrial housings, heat sinks, structural parts, and precision-engineered castings.

How to Choose the Right Aluminium Casting Company?

Use the following criteria to shortlist aluminium foundries that best match your technical and commercial requirements.

Casting capability: Ensure the foundry supports the required process such as die casting, sand casting, or permanent mold casting.

Quality standards: Look for ISO, IATF, or aerospace certifications, along with robust inspection and testing systems.

Material expertise: Experienced foundries offer a wide range of aluminium alloys tailored to strength, thermal, or corrosion requirements.

Engineering support: Design-for-manufacturing (DFM), mold flow simulation, and prototype services reduce development risk.

Production capacity: Confirm the foundry can handle your expected volumes and growth plans.

Post-processing services: Machining, heat treatment, surface finishing, and assembly services simplify supply chains.

Tips to Reduce Costs When Sourcing Aluminium Castings Worldwide

These practical tips help minimize total project cost while maintaining consistent quality.

- Focus on total cost, not unit price: Lower scrap rates, stable quality, and reliable delivery reduce hidden expenses.

- Optimize part design: Simplifying geometry and wall thickness lowers tooling and casting costs.

- Select the right alloy: Avoid over-specifying mechanical properties that increase material costs unnecessarily.

- Leverage standard tooling: Where possible, use existing mold bases or standard dies.

- Consolidate suppliers: Bundling multiple parts with one foundry improves pricing leverage.

- Plan volumes early: Accurate forecasts help foundries optimize production schedules and offer better rates.

FAQ: Aluminium Casting Products

Q1: What types of aluminium casting products are commonly available?

Aluminium casting products include automotive engine parts, gearbox housings, pump and valve bodies, motor housings, heat sinks, structural brackets, lighting components, and custom industrial parts. Foundries can produce both standard and fully customized components.

Q2: Which aluminium casting process is best for my product?

The best process depends on part size, complexity, tolerance, and volume. High-pressure die casting suits high-volume, precision parts; sand casting is ideal for large or low-volume components; permanent mold and low-pressure casting balance strength and surface quality.

Q3: What aluminium alloys are most commonly used in casting products?

Common casting alloys include A356, A380, ADC12, AlSi7Mg, and AlSi10Mg. Each alloy offers different advantages in strength, fluidity, corrosion resistance, and machinability.

Q4: Can aluminium casting products be machined or surface treated?

Yes. Most aluminium casting products support CNC machining, heat treatment, anodizing, powder coating, painting, polishing, and plating to meet functional and aesthetic requirements.

Q5: How do I ensure quality and consistency for aluminium casting products?

Quality is ensured through material certification, process control, dimensional inspection, non-destructive testing, and sample approval. Choosing a foundry with proven quality systems and inspection capabilities is essential.

Q6: What information is needed to quote an aluminium casting product?

Suppliers typically require 2D/3D drawings, alloy specification, surface finish requirements, annual quantity, machining details, and application environment to provide an accurate quotation.

Conclusion

The global aluminum casting industry is defined by a group of established leaders, primarily based in the United States, with decades of expertise in sand, permanent mold, and die casting processes. Companies like Wisconsin Aluminum Foundry, Le Sueur Incorporated, and Alcast Company have built strong reputations by serving demanding sectors such as aerospace, defense, and heavy trucking with high-integrity, pressure-tight components. These foundries are characterized by their deep-rooted histories, often spanning over 75 years, and a strong focus on vertical integration, offering everything from in-house tooling and machining to full assembly.

While these Western manufacturers excel in traditional markets, the global supply chain increasingly demands a combination of advanced engineering, high-volume production capability, and competitive pricing. This is where a new generation of globally-focused suppliers has emerged to meet the need for complex, precision aluminum castings on an international scale. Leading this charge from China is NINGBO INNOVAW MECHANICAL CO., LTD (Innovaw).

Since 1998, Innovaw has established itself as a premier aluminum die casting manufacturer and comprehensive solutions provider. Operating multiple specialized foundries certified to IATF 16949 and ISO 9001:2015, Innovaw offers complete vertical integration from rapid prototyping and advanced mold flow simulation to high-volume mass production. With expertise spanning high-pressure die casting, low-pressure casting, gravity casting, and precision CNC machining, Innovaw serves a global clientele in the automotive, aerospace, marine, and industrial sectors, combining two decades of technical expertise with modern manufacturing efficiency and rigorous quality control.

Related Articles

- Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World

- Top 10 Aluminum Pressure Die Casting Manufacturers and Suppliers in the World

- Top 10 Aluminium Gravity Casting Factories and Suppliers in the World

- Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World

- Top 10 Aluminium Investment Casting Factories and Manufacturers in the World

- Top 10 Aluminum CNC Machining Factories and Manufacturers in the World

-

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026 -

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World -

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China -

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

-

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China -

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World -

Feb 11, 2026Top 10 Aluminium Gravity Casting Factories and Suppliers in China

Feb 11, 2026Top 10 Aluminium Gravity Casting Factories and Suppliers in China -

Feb 06, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Feb 06, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in China