Aluminum Die Casting Cost Breakdown: From Material to Machining

Wondering why aluminum die casting cost can vary so widely from one part to another and what really drives these expenses in the industry? There are various aluminum casting processes in the market, including high-pressure die casting, low-pressure die casting, gravity casting, investment casting, and sand casting. Selecting the appropriate casting method according to different product requirements will significantly affect the final cost.

In today’s market, factors such as raw material prices, mold complexity, machine tonnage, and machining requirements all influence the overall aluminum die casting cost. This article focuses on high-pressure aluminum die casting as an example to explain these factors. Understanding them helps engineers, product designers, and procurement professionals make smarter decisions while staying competitive.

This article breaks down the key components of aluminum die casting, from materials to machining, highlighting how choices at each stage impact cost. By exploring raw material selection, production scale, and post-processing, you will gain insights to optimize production and control expenses effectively—keep reading to learn how to make informed casting and investment decisions.

Breakdown of Aluminum Die Casting Manufacturing Costs

To better understand how each factor contributes to the overall cost, we will examine the main components step by step, from raw materials to batch size considerations. This detailed breakdown will provide a clear picture of what drives aluminum die casting expenses and where potential savings can be achieved.

- 1. Raw Materials

- 2. Material Loss

- 3. Mold Cost

- 4. Machine Cost

- 5. Post-Casting Processing

- 6. Machining Cost

- 7. Surface Treatment

- 8. Packaging and Shipping

- 9. Taxes and Fees

- 10. Batch Size

1. Raw Materials

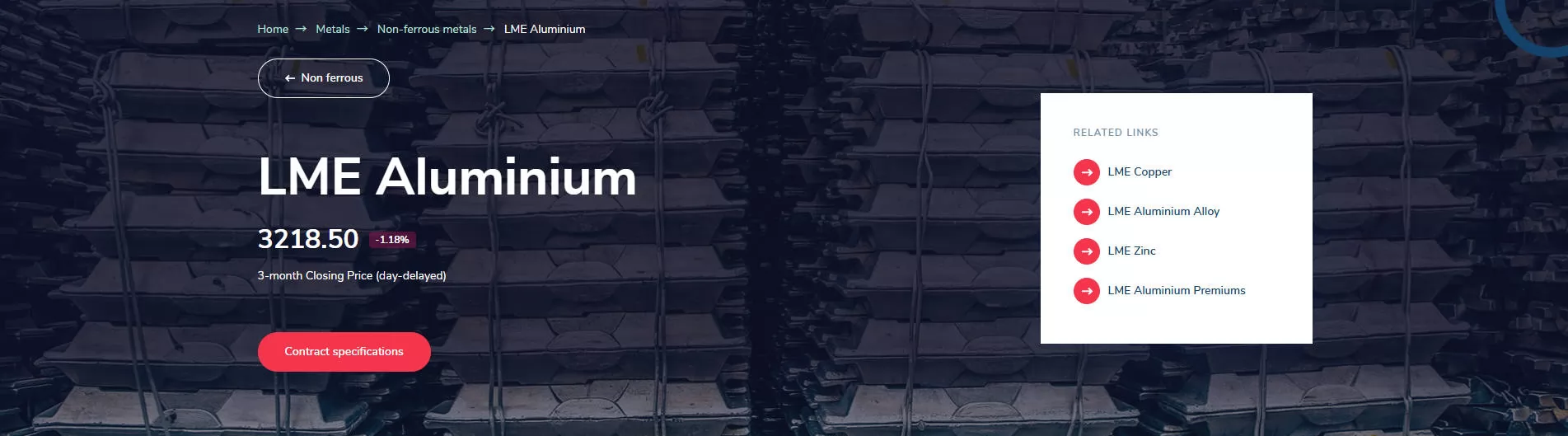

In large-scale aluminum casting production, raw material cost always occupies the largest portion of total cost. The cost depends on the alloy type and the weight of the casting. For reference, the following chart shows aluminum prices on the London Metal Exchange on January 30, 2026.

As aluminum prices continue to rise, raw material costs account for an increasingly larger proportion of total aluminum casting costs. Different types of aluminum, such as ADC12 and K-Alloy, have different prices. Typically, raw material costs account for 40% to 60% of total aluminum casting costs. This portion of the cost is usually calculated according to the international standard aluminum price at the time of order, following the market. We generally use “unit material price × product weight” to determine material costs; the heavier the product, the higher the material cost.

2. Material Loss

Although aluminum is a recyclable material, and scrap and defective parts in the casting process can be reused, some material loss is inevitable. Even though engineers carefully consider product design and try to minimize waste such as runners and gates, material loss still occurs. In the industry, material loss during casting typically ranges from 5% to 10%, while Innovaw Mechanical can control the loss ratio to 5% or even lower.

3. Mold Cost

Professionals in manufacturing know that molds, materials, and operational costs are the main drivers of aluminum casting costs. Among various aluminum casting processes, high-pressure die casting molds usually have the highest cost. This is mainly because:

- The structure of high-pressure molds is the most complex, including multiple sliders, cooling channels, complex injection systems, ejection, reset, venting, and overflow mechanisms.

- Material and heat treatment requirements are the highest due to extreme working conditions, requiring high-end mold steel such as H13 and surface nitriding.

- High precision and long lifespan are required. Mold clearance is small, cavity precision is high, and lifespan is typically 50,000 to 100,000 cycles.

Thus, a standard high-pressure die casting mold can cost from several thousand to tens of thousands or even hundreds of thousands of US dollars, depending on product design. This can be a significant initial cost for customers; however, because high-pressure molds have a very long service life, under optimal conditions, mold inserts can last 50,000 to 100,000 parts. When spread over the number of products, mold cost per part may not be very high.

Additionally, there may be subsequent costs for trimming dies, specialized CNC fixtures, and other mold-related expenses depending on product requirements.

4. Machine Cost

In high-pressure die casting machines, the cost varies significantly depending on the machine tonnage. For example, at Innovaw Casting, machines range from 280 tons to 3,000 tons, and the operational costs vary greatly. This portion of cost typically includes depreciation of the die casting machine, energy consumption, system operation costs, maintenance and repair allocation, and basic labor. The formula for this cost can be expressed as: required clamping force × cycle time × unit time equipment cost. Therefore, if a casting can be produced on a smaller machine, significant cost savings can be achieved.

Case example: In 2025, a customer requested production of a 70cm × 5cm aluminum part. Conventionally, this would require an 800-ton die casting machine, but after precise engineering design, a 500-ton machine was used instead, saving approximately 10% in production costs. The customer was very satisfied with the quote.

Furthermore, mold design for part ejection is also an important cost factor. Single-cavity, double-cavity, or even four-cavity molds create significant cost differences. Therefore, excellent mold design can greatly reduce costs. Machine cost typically accounts for 5%–10% of total cost.

5. Post-Casting Processing

After coming out of the die casting machine, castings require trimming of gates, flash removal, deburring, and sometimes polishing. Differences in product requirements and designs result in significant cost variations. This stage is mainly labor-intensive and reflects efficiency control. As modern manufacturing increasingly adopts automation, this cost is decreasing. Typically, post-casting processing accounts for 1%–3% of total cost.

6. Machining Cost

Except for a very few aluminum castings that require no machining, almost all products undergo post-casting machining. Machining cost varies widely depending on processing time, equipment type, machining complexity, precision requirements, batch size, and casting quality stability and process risks. The most important factor is machining time, which depends on the number of machining steps, time per step, amount of finishing, and whether deep drilling, threading, or cavity milling is required. Simply put, the longer the machining time, the higher the quote.

Machining difficulty (shape + process risk), precision, and surface finish requirements are key factors driving cost differences. Different dimensional tolerances, surface roughness, and flatness requirements can lead to geometric increases in cost. Therefore, CNC machining is a major component of total aluminum casting cost and can vary widely, sometimes accounting for only 10% or up to 60% of total cost.

7. Surface Treatment

Depending on the customer's product requirements, surface treatments such as powder coating, anodizing, chromitization, passivation and phosphating, Teflon, or nickel plating can result in different costs.

8. Packaging and Shipping

While packaging and transportation costs are generally minor, they are not negligible and may account for 2%–3% of total cost.

9. Taxes and Fees

As a law-abiding company, taxes must be considered in cost accounting, which can account for up to 10% of total cost.

10. Batch Size

In modern manufacturing, raw material cost is important but not decisive. It mainly depends on product design and requirements. The simpler the design, the closer the price approaches raw material cost; the more complex the product, the smaller the proportion of raw material cost in total cost. Another key factor is batch size. Due to economies of scale and mold amortization, small-scale and large-scale production result in different unit costs. For example, a batch of 5,000 die castings may cost $10 per part, whereas 50,000 pieces may reduce to $8 per part.

Data Collection and Cost Estimation Model for Quoting

To provide accurate quotes, Innovaw engineers need precise data collection and reliable modeling technology to estimate aluminum casting costs accurately. Advanced methods help predict costs before production and ensure products remain competitive throughout their lifecycle.

Engineers first conduct preliminary DFM (Design for Manufacturability) analysis, which, besides confirming manufacturability, focuses on cost control, including mold structure, machine tonnage, process stability, and minimizing post-processing and scrap rates.

After DFM analysis, engineers build CAD models using key geometric product data to determine volume and weight, then use London Metal Exchange (LME) data to set per-kilogram aluminum casting cost. Combined with historical company production data, reasonable cost estimations are made for each stage, enabling delivery of professional and reliable quotes to clients.

Conclusion

Aluminum casting cost analysis is a comprehensive process. For the same part, different manufacturers, based on technical capability, production capacity, and quality control, can provide quotes that vary significantly. These cost factors indicate that careful selection of the process flow and qualified manufacturers is critical, considering product complexity and expected production volume.

Aluminum die casting involves multiple factors that drive cost, from raw material selection and mold complexity to machine tonnage, machining, and surface finishing. Each stage has a significant impact on the overall expense, and careful consideration of product design, production scale, and process efficiency is essential to optimize costs and maintain competitiveness in today’s market.

At Innovaw, a leading Chinese aluminum casting company, we combine advanced engineering, precise DFM analysis, and reliable production capabilities to help clients control costs without compromising quality. By leveraging our expertise in high-pressure die casting, we provide tailored solutions that maximize efficiency, reduce waste, and ensure consistent, high-quality parts for a wide range of industries.

-

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026 -

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World -

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China -

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

-

Jan 30, 2026Aluminum Die Casting Cost Breakdown: From Material to Machining

Jan 30, 2026Aluminum Die Casting Cost Breakdown: From Material to Machining -

Jan 28, 2026Top 10 Zinc Pressure Die Casting Manufacturers and Suppliers in the World

Jan 28, 2026Top 10 Zinc Pressure Die Casting Manufacturers and Suppliers in the World -

Jan 28, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026

Jan 28, 2026Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026 -

Jan 26, 2026A Complete Guide to Die Casting: Types, Materials, and Applications

Jan 26, 2026A Complete Guide to Die Casting: Types, Materials, and Applications