Aluminum Casting: Processes, Alloys, Properties, and Applications

_1768813310_WNo_1600d900.webp)

Why is aluminum casting essential in industries like automotive and aerospace? Its combination of lightweight, strength, and design flexibility makes it a key manufacturing solution.

This article explains the main processes, alloys, and properties of aluminum casting, helping engineers and designers make efficient, high-performance choices in a market moving toward lighter, durable materials.

We cover casting techniques, material options, and applications, highlighting the importance of selecting the right method—read on to learn how smart choices can improve performance and innovation.

1. Introduction to Aluminum Casting

Aluminum casting is a process in which molten aluminum or aluminum alloy is poured into a mold to create a solid component. It is widely used in industries that require lightweight, durable, and complex-shaped parts.

Key features of aluminum casting include:

- Design flexibility: Can produce complex geometries, internal cavities, and thin walls that are difficult to achieve with machining or forging.

- Cost efficiency: Reduces post-machining and assembly requirements.

- Scalability: Suitable for both small precision parts and large structural components.

- Lightweight: Aluminum’s low density helps reduce overall product weight, ideal for automotive and aerospace applications.

Common casting methods include sand casting, die casting, permanent mold casting, investment casting, and centrifugal casting. Each method offers trade-offs in terms of precision, surface finish, and production volume.

2. Mechanical and Physical Properties of Aluminum Castings

Aluminum castings combine strength, low weight, and corrosion resistance. Properties vary depending on alloy composition, casting process, and post-casting treatments.

| Property | Typical Values / Notes |

|---|---|

| Density | 2.65–2.75 g/cm³ |

| Tensile Strength | 180–310 MPa, varies by alloy and heat treatment |

| Elongation / Ductility | 1–12%, dependent on alloy and process |

| Corrosion Resistance | High; enhanced with Mg or Si alloying |

| Thermal Conductivity | 100–180 W/m·K, suitable for heat dissipation |

| Elastic Modulus | ≈69 GPa, moderate stiffness |

These characteristics make aluminum castings ideal for automotive parts, industrial equipment, and structural components where weight reduction and corrosion resistance are important.

3. Aluminum Alloys for Casting

Aluminum casting alloys are selected based on mechanical requirements, corrosion resistance, castability, and intended application. Major types include:

| Alloy Type | Key Features | Typical Applications |

|---|---|---|

| Al‑Si Alloys | Excellent fluidity, low shrinkage; heat-treatable for higher strength | Automotive structural parts, wheels, machinery components |

| Al‑Si‑Cu Alloys | Higher strength and thermal stability | Engine blocks, transmission housings, high-temperature components |

| Al‑Mg Alloys | Improved corrosion resistance; moderate strength | Marine applications, outdoor equipment, structural parts |

| High-Pressure Die Casting Alloys (A380, A383) | Optimized for thin-walled, high-precision components | Electronics housings, automotive components, consumer products |

When selecting an alloy, designers must balance strength, corrosion resistance, thermal performance, and manufacturability to ensure reliable and efficient production.

4. Manufacturing Techniques of Aluminum Castings

Aluminum casting involves several distinct manufacturing techniques, each suited to different part geometries, production volumes, and performance requirements. Selecting the right method depends on factors such as precision, surface finish, and cost.

4.1 Sand Casting and Shell Mold Variants

Sand casting uses sand-based molds to form components. It is highly versatile and suitable for large or complex parts, but surface finish and dimensional accuracy are limited.

| Process | Advantages | Limitations | Typical Applications |

|---|---|---|---|

| Traditional Sand Casting | Low tooling cost, flexible for large parts | Lower dimensional accuracy, rough surface | Industrial machinery, large structural components |

| Shell Mold Casting | Improved surface finish, finer details | Higher cost than sand casting | Medium-sized automotive and aerospace parts |

4.2 Permanent Mold and Gravity Casting

Permanent mold casting, also called gravity die casting, uses reusable metal molds. The molten aluminum fills the mold by gravity, producing better surface finish and dimensional control than sand casting.

- Suitable for medium-to-high volume production

- Common alloys: Al‑Si and Al‑Si‑Cu systems

- Typical parts: Engine brackets, housings, structural components

4.3 High-Pressure Die Casting

High-pressure die casting injects molten aluminum into a steel mold under high pressure. This method is ideal for thin-walled, high-volume parts with tight tolerances.

| Feature | Description |

|---|---|

| Production Volume | High – suitable for mass production |

| Precision | Excellent dimensional accuracy |

| Surface Finish | Smooth, minimal post-processing required |

| Limitations | High tooling cost, limited to smaller or medium-sized parts |

4.4 Investment and Precision Casting

Investment casting (lost-wax) produces high-precision parts with complex geometries. It is used when dimensional accuracy and surface finish are critical.

- Wax or foam patterns are coated with ceramic or plaster to create the mold

- Molten aluminum replaces the pattern after it is removed

- Ideal for aerospace components, turbine housings, and intricate machine parts

- Limitations: Slower production, higher cost per part compared to die casting

4.5 Centrifugal and Specialty Casting Methods

Centrifugal casting uses rotational force to distribute molten metal in a mold, producing dense, defect-free parts, often with cylindrical geometry.

| Method | Best For | Advantages | Limitations |

|---|---|---|---|

| Centrifugal Casting | Pipes, bushings, bearings | Dense structure, minimal defects, good mechanical properties | Limited to rotationally symmetric parts |

| Specialty Casting | Custom or unusual geometries | Adaptable for unique designs | Higher cost, limited production volume |

5. Process Selection and Comparative Analysis

Choosing the right aluminum casting process depends on part complexity, production volume, and required performance. Common methods include:

-

Investment Casting

Best for complex shapes with fine details. Advantages include high dimensional accuracy, excellent surface finish, and the ability to produce intricate geometries. Limitations are slower production and higher per-part cost.

-

High-Pressure Die Casting

Ideal for high-volume, thin-walled components. Offers excellent precision, smooth surfaces, and rapid production rates. Limitations include high tooling cost and size restrictions.

-

Gravity-Fed Permanent Mold Casting

Suitable for medium-volume structural parts. Provides better surface finish and dimensional accuracy than sand casting at a moderate tooling cost. Limitations include restricted mold complexity and lower production speed compared to die casting.

-

Sand Casting

Used for low-volume, large, or simple parts. Advantages are flexibility and low tooling cost. Limitations include lower surface finish and dimensional accuracy.

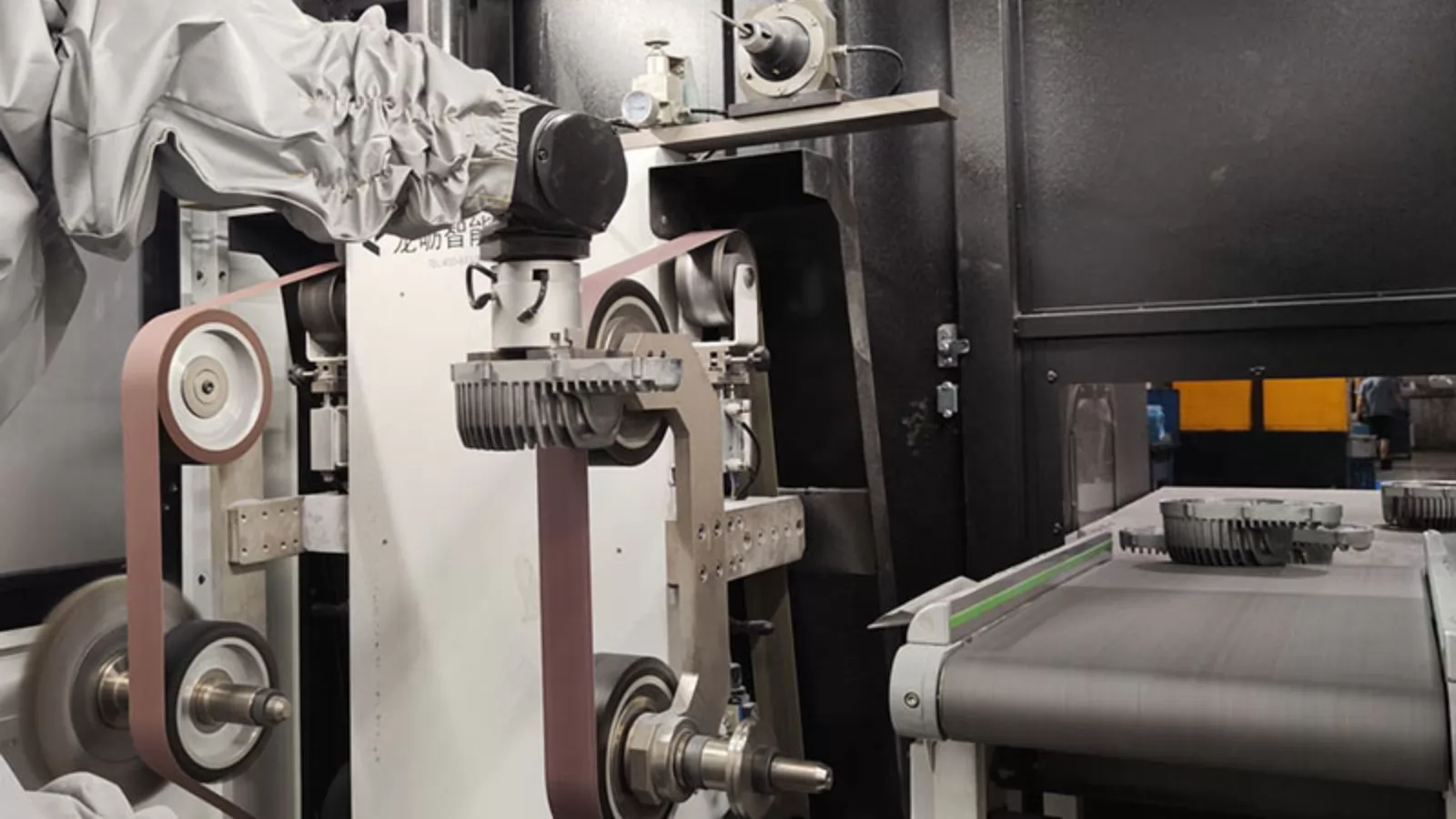

6. Post-Casting Operations and Surface Treatments

After casting, aluminum components often require additional operations to achieve final dimensions, surface quality, and mechanical performance. Heat treatment can significantly improve strength and hardness, while machining ensures that critical features and tolerances are met. Surface finishing processes, such as anodizing, polishing, or coating, not only enhance aesthetics but also provide corrosion protection. Cleaning and deburring are also important to remove any residual material and prepare the part for assembly or further finishing.

Proper post-casting treatments are essential to ensure that the component meets functional requirements, extends service life, and maintains consistent quality across production batches.

7. Sustainability and Recycling of Aluminum Castings

Aluminum castings are highly sustainable due to the metal’s excellent recyclability. Recycled aluminum retains the same material properties as primary aluminum, making it suitable for repeated use in industrial applications. Using recycled aluminum consumes only a fraction of the energy required to produce primary metal, reducing greenhouse gas emissions and resource consumption. This makes aluminum castings an environmentally responsible choice for automotive, aerospace, construction, and consumer products.

Innovaw emphasizes sustainable manufacturing practices by incorporating recycled aluminum into production whenever possible, ensuring that high-quality components are delivered with a reduced environmental footprint.

8. Applications of Innovaw Aluminum Cast Components

Innovaw aluminum castings are engineered for a broad range of industrial and consumer applications, combining lightweight, durability, and corrosion resistance. In the automotive sector, they are used for engine components, transmission housings, and other structural parts to reduce weight while maintaining strength. Bicycle components benefit from precision castings that ensure safety and performance, while agricultural machinery castings provide durability and wear resistance for heavy-duty equipment.

In the construction and home improvement sector, Innovaw supplies door and window castings that meet exacting standards for strength and appearance. Electric motor and energy castings support industrial and renewable energy applications, offering stability and precision for mechanical and electrical performance. Gas meter, instrument, and meter castings provide reliable housings for measurement devices, while LED work light castings ensure thermal management and structural integrity.

Marine castings are designed for harsh environments, with superior corrosion resistance, and medical equipment castings meet stringent standards for precision and reliability. Water heater castings provide both durability and efficient heat transfer, demonstrating the versatility of Innovaw aluminum casting solutions across diverse industries.

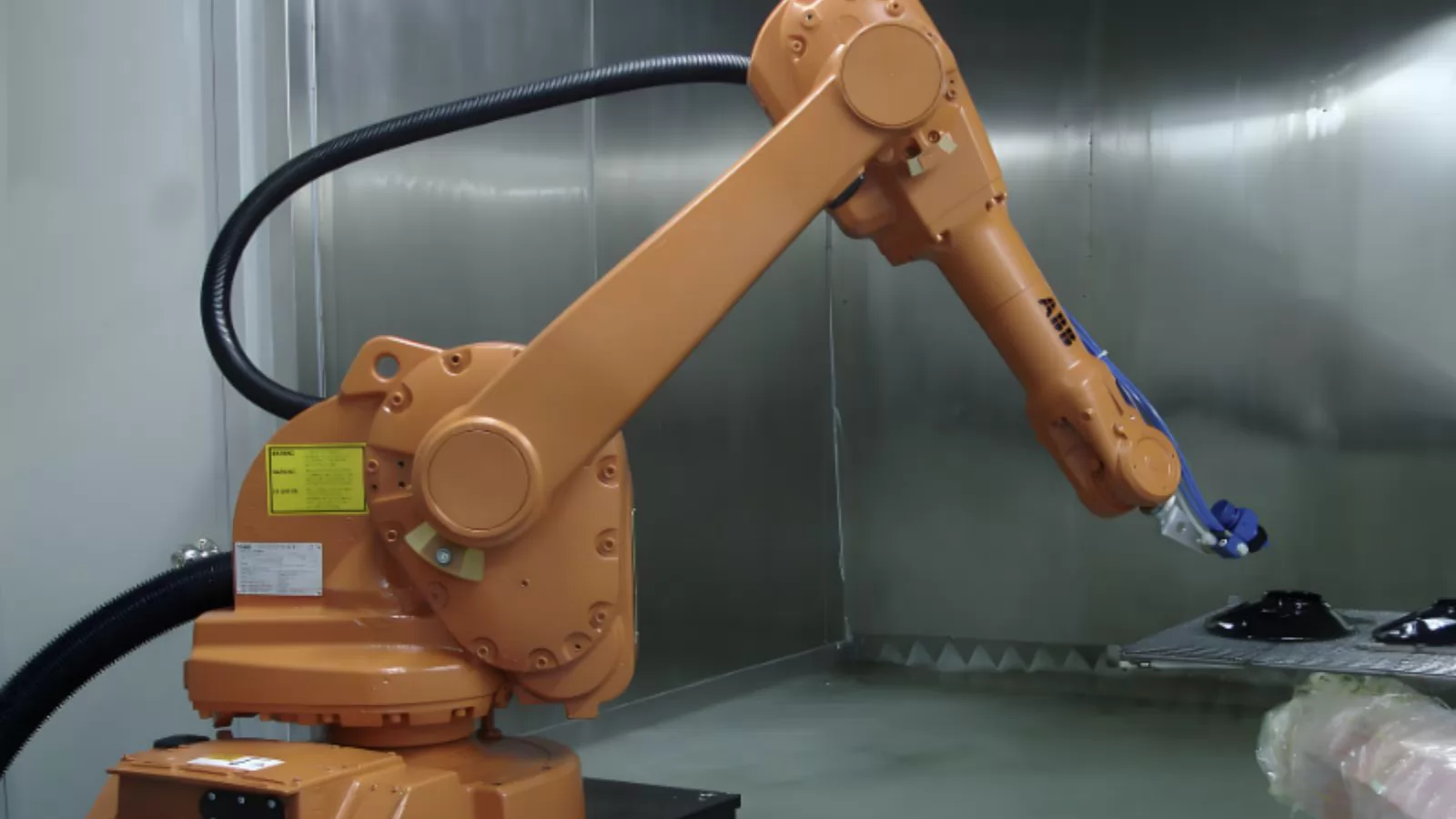

9. Innovaw Aluminum Casting Services

Innovaw offers a comprehensive range of aluminum casting services to support customers from design to final production. Our engineering team provides guidance on material selection, casting methods, and manufacturability to ensure optimal performance and cost efficiency. Whether the project requires sand casting, high-pressure die casting, investment casting, or specialty techniques, Innovaw can deliver precision components tailored to specific industry requirements.

We also provide post-casting services, including heat treatment, machining, and surface finishing, to ensure components meet dimensional tolerances, mechanical properties, and aesthetic standards. Rigorous quality assurance measures, including inspection and testing, guarantee consistent performance and reliability for all applications. This end-to-end service approach enables Innovaw to deliver high-quality aluminum castings across automotive, industrial, consumer, and specialty sectors.

10. Frequently Asked Questions About Aluminum Casting

1. Is aluminum casting better than iron casting?

Aluminum is lighter and more corrosion-resistant, with good thermal and electrical conductivity. Iron provides higher stiffness and heat resistance. The choice depends on the specific performance requirements of the application.

2. What is the difference between cast and forged aluminum?

Cast aluminum is poured into molds, allowing complex shapes, but generally has lower tensile strength. Forged aluminum is mechanically worked, resulting in higher strength and fatigue resistance.

3. Are there finishing processes for aluminum castings?

Yes, including heat treatment, machining, anodizing, painting, and powder coating. These processes enhance mechanical properties, corrosion resistance, and surface appearance.

4. How should cast aluminum be cleaned and maintained?

Regular cleaning with mild detergents and non-abrasive methods is recommended. Surface treatments such as anodizing or protective coatings help maintain corrosion resistance and aesthetic quality over time.

-

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in the World 2026 -

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World

Oct 22, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in the World -

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China

Nov 26, 2025Top 10 Aluminium Low Pressure Die Casting Manufacturers in China -

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

Dec 12, 2025Top 10 Aluminium Die Casting Manufacturers and Suppliers in China

-

Mar 05, 2026Investment Casting: Process, Benefits, Materials, and Industrial Applications

Mar 05, 2026Investment Casting: Process, Benefits, Materials, and Industrial Applications -

Mar 02, 2026What Type of Sand Is Used for Sand Casting?

Mar 02, 2026What Type of Sand Is Used for Sand Casting? -

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in China -

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World

Feb 11, 2026Top 10 Aluminium Investment Casting Factories and Manufacturers in the World